I have a question regarding bowl blending on my small log cylinder head.

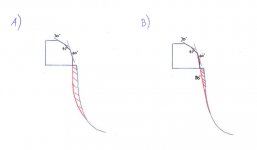

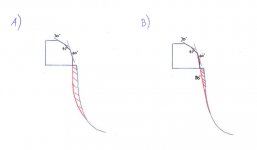

My car is just a weekend cruiser but with some simple upgrades (ignition, carburetor, header and exhaust, little higher compression). My machine shop put new hardened seats in my cylinder head and they did a three angle valve job (60°, 45°,30°). As you can see, there is a ridge (max. 0.04” wide) between the bowl and the base of the seat insert. Now I have two options for blending (and I sonic tested the head, I have enough material to do both variations) (see also picture attached):

A) I cut straight (90°) below the 60° angle and the blend it into the bowl (so the 4 angles would be 30°,45°,60°,90° and blending)

or

B) I make an 80° cut that cleans up the 60° angle and then blend it into the bowl. (here I would get rid of the 60° angle and replace it with the 80° angle. The 3 angles would be 30°,45°,80° and blending)

What would make more sense (A or B) for a cruiser car with a stock camshaft that is driven mostly in town, where torque matters?

My car is just a weekend cruiser but with some simple upgrades (ignition, carburetor, header and exhaust, little higher compression). My machine shop put new hardened seats in my cylinder head and they did a three angle valve job (60°, 45°,30°). As you can see, there is a ridge (max. 0.04” wide) between the bowl and the base of the seat insert. Now I have two options for blending (and I sonic tested the head, I have enough material to do both variations) (see also picture attached):

A) I cut straight (90°) below the 60° angle and the blend it into the bowl (so the 4 angles would be 30°,45°,60°,90° and blending)

or

B) I make an 80° cut that cleans up the 60° angle and then blend it into the bowl. (here I would get rid of the 60° angle and replace it with the 80° angle. The 3 angles would be 30°,45°,80° and blending)

What would make more sense (A or B) for a cruiser car with a stock camshaft that is driven mostly in town, where torque matters?