You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Upgraded cooling fan?

- Thread starter gserafini

- Start date

This relates to all small sixes

TrickSix

Famous Member

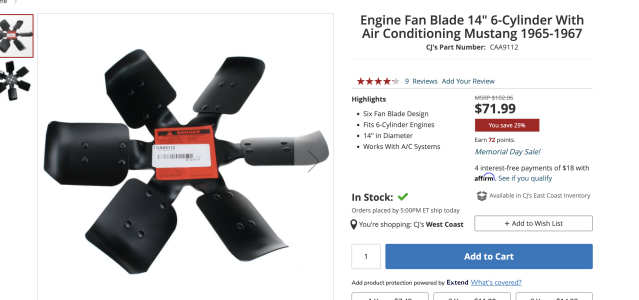

As an ex-AC car, mine still has the 6-bladed fan. It does really suck wind, even without a shroud. One difference at least between my factory fan and this one is that the factory fan blades aren't mounted in a symetrical pattern. I think it might be to cut down on noise or vibration or something.

looks like something off the front of a mustang p51 fighter. Run an electric one!

Last edited:

It does???looks like something off the front of a mustang p51 fighter. Run an electric one!

I want one!!

frozenrabbit

Well-known member

I think a shroud would make a bigger difference.

frozenrabbit

Well-known member

3 row, brass/copper, never ran aluminum. The welds on so many of the aluminum box tank ones look like garbage, but there are several places selling aluminum with stamped tanks.

3-row is quite a bit more cooling capacity. Eliminated all my heating issues on a pickup- in the melt-belt.Thanks for the input! Looks like most of you are running a 3 row. I was convinced there wasn't enough difference and that the 2row would give me more fan clearance. But hey might as well go 3!

PSIG

Famous Member

Aluminum can have standard tube size, or wide tubes for better cooling area, due to increased aluminum strength. Look closely at info. A 2-row aluminum can cool better than a 3-row copper radiator, while a 3-row aluminum not as well, if the tubes are smaller. This IMO is part of why there is so much contention over copper or aluminum, as there are so many differences that affect performance. Add to that the wide range of quality and costs for either, and it's a mess.

TrickSix

Famous Member

With a Spectra CU1463 radiator and my stock pulley, spacer, and 6-bladed fan I have about 7/8" clearance between the fan and the radiator, a comfortable distance. And that wasn't much closer than with the original radiator in, though that was a special AC specific version too, I'm not sure if it was thicker than the standard radiator. With an after-market fan you'll be taking a chance, but you can put a shorter spacer on I suppose.I was convinced there wasn't enough difference and that the 2row would give me more fan clearance.

PSIG

Famous Member

Adding an example of tube width. While the example is for a classic car, it serves for concept example. Copper alloy is typically 3/8" to 1/2" flow tubes, for 3-rows x .375 = 1.125" total, while the popular ACP aluminum 3-row is 3/4" tubes (2.25"), and the 2-row AL uses 1-1/4" tubes (2.5") It's easy to see why they claim the 2-row is the performance version in this case.

Just an example, they are popular but I don't have any connection. Note the heat transfer of aluminum is nearly half that of copper, but that's not the only parameter. We can add fin count and other parameters, but tube size versus rows is a first-level biggie.

Just an example, they are popular but I don't have any connection. Note the heat transfer of aluminum is nearly half that of copper, but that's not the only parameter. We can add fin count and other parameters, but tube size versus rows is a first-level biggie.

Similar threads

All Small Six

New Adventures in electrics fans and inline 6’s

- Replies

- 22

- Views

- 2K

All Small Six

1967 Mustang - ACP two row radiator w/factory air

- Replies

- 16

- Views

- 2K

- Replies

- 5

- Views

- 564

- Replies

- 5

- Views

- 369