Howdy guys,

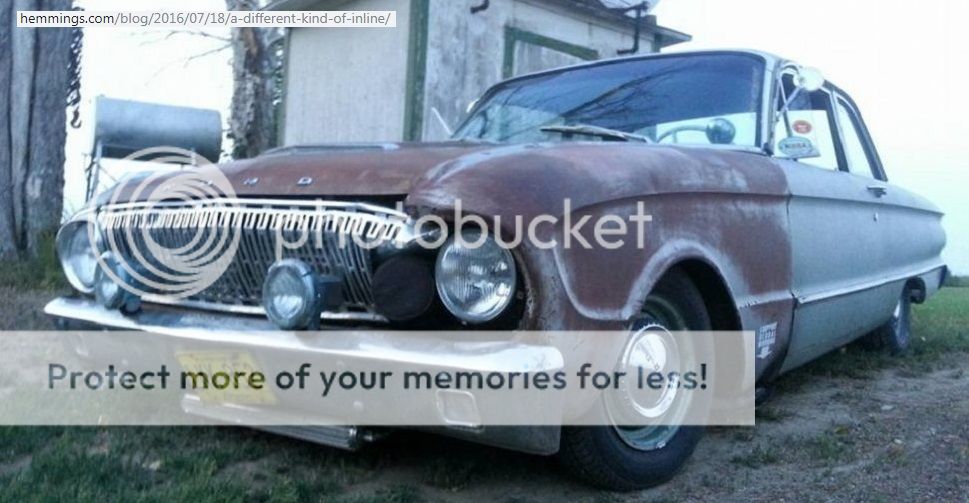

I'm looking into maybe lightly boosting my 200 in my 65 Ranchero. Heres what I have:

66 200 block (dual bolt pattern) stock internals currently including cam. Engine is healthy. Holding hot static 200psi average. (Plan on fixing how high compression is when new head goes on).

1980 2V converted head, 1.5 exhaust, upgraded springs and retainers. Valve work (not yet on)

256-256 Schneider cam, .420 lift and 112 lobe sep (not yet bought)

1968 Autolite 2100 1.08

1968 exhaust manifold

1985 Turbo SVO T5 WC, 4.03 1st and .81 5th

1966 8" with 2.8 gears

AFR gauge

I have a set of dual out VI headers and i was going to keep it NA but now I'm thinking of boosting it. I was originally thinking supercharging with a paxton style but they be expensive and i was reading they're high end power not low end. I want low end. I cruise at 2000 doing 70mph. So i read about turbocharging....

I'm looking at keeping it 6psi or less. I want something simple to run plumbing wise, make most of its torque from 1500-4000, and no intercooler. How attainable is this and can this be done cheaply? Am i better off just doing NA and keeping my cam i have picked out, or should i turbo it and pick a different cam? Are my stock 66 internals good enough for low boost? This is my DD and I want something fun, yet reliable.

Thanks,

Ryan

I'm looking into maybe lightly boosting my 200 in my 65 Ranchero. Heres what I have:

66 200 block (dual bolt pattern) stock internals currently including cam. Engine is healthy. Holding hot static 200psi average. (Plan on fixing how high compression is when new head goes on).

1980 2V converted head, 1.5 exhaust, upgraded springs and retainers. Valve work (not yet on)

256-256 Schneider cam, .420 lift and 112 lobe sep (not yet bought)

1968 Autolite 2100 1.08

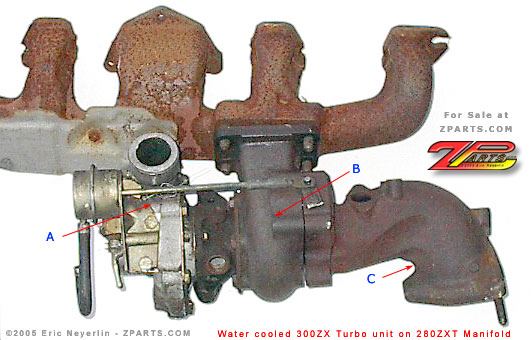

1968 exhaust manifold

1985 Turbo SVO T5 WC, 4.03 1st and .81 5th

1966 8" with 2.8 gears

AFR gauge

I have a set of dual out VI headers and i was going to keep it NA but now I'm thinking of boosting it. I was originally thinking supercharging with a paxton style but they be expensive and i was reading they're high end power not low end. I want low end. I cruise at 2000 doing 70mph. So i read about turbocharging....

I'm looking at keeping it 6psi or less. I want something simple to run plumbing wise, make most of its torque from 1500-4000, and no intercooler. How attainable is this and can this be done cheaply? Am i better off just doing NA and keeping my cam i have picked out, or should i turbo it and pick a different cam? Are my stock 66 internals good enough for low boost? This is my DD and I want something fun, yet reliable.

Thanks,

Ryan