Howdy fellas! So, after driving my old Ranchero for a little over a year now, my thoughts on building an engine have changed. Ya see, it has the 200 ci with a three on the column and I think it’s bone stock except for an electronic ignition to replace the points. The clutch is terrible, slips so bad that sometimes if I’m going pretty slow (like 35mp) in third gear and floor the pedal, it slips. Now don’t misunderstand, it will slip in all gears, I just used third to illustrate just how bad it slips. I have pretty large (at least for a Ranchero) AT tires, I think they are 28”, and I know these suck a lot of power.

But with all that said, I’m really not dying for more power. The great thing is, it’s my little pickup truck, and I don’t wanna go fast in it. It has plenty enough power to get the job done, I just need to address a few problems, and a slight power boost would be nice. But shoving in a 250 ci with all the bells and whistles just doesn’t seem needed to me anymore.

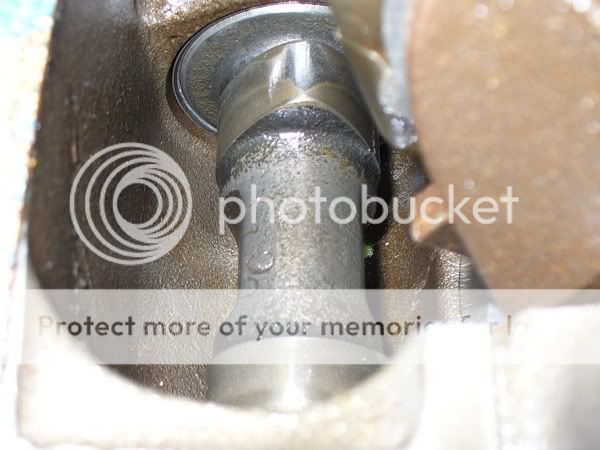

So, here’s the dealio: I have a cylinder head from an ’82 fairmont that is currently at the machinist where it is being cleaned up and shaved down by .070”. I will be putting this on my original 200 ci that is already in the car, it’s in great shape and doesn’t need a rebuild-so why do it? I’ll put in a mild cam designed for torque, and some headers. And I have a T-5 from a ’95 S-10 and have confirmed it has the good gear ratio and that modern driveline can make a clutch for me and it will work. I’ve also got an 8” rear end from a Maverick that will go in with either 3.50 or 3.80 gears. (remember, big tires)

Where I am stuck, is with the carb choice and cam. For the cam, I have no idea-none. Hydrolic, solid lifters, all that crap, I just simply don’t have a clue what would work for my application.

With the carb, I’m kicking myself in the arse for not getting the carb that was on the Fairmont. I just remember seeing all those vacuum hoses, and coupled that with the thinking at the time that I wanted to really get a lot of power from my 250 ci that I was going to build, and I thought I would have no use for it.

So what I have as far as carbs, is the original Autolite 1100 that is on my 200, but it needs a rebuild (leaking when I shut the engine off), and I have the Carter RBS from the 1975 250 ci sitting in my garage and will definitely need a rebuild too.

So, what’s the best 1v carb to run? Keeping in mind that my head is the good log head from ’82 so it has a big ole carb opening. Should I rebuild my Carter, buy a different 1v, purchase a 2v and get an adapter, or have the 2v modified to directly accept a 2v?

Which, speaking of modifying the log head- no one in my area will do it, so who would I send it to an how much does it cost?

I know, I’m wordy, sorry.

Thanks for your advice in advance.

But with all that said, I’m really not dying for more power. The great thing is, it’s my little pickup truck, and I don’t wanna go fast in it. It has plenty enough power to get the job done, I just need to address a few problems, and a slight power boost would be nice. But shoving in a 250 ci with all the bells and whistles just doesn’t seem needed to me anymore.

So, here’s the dealio: I have a cylinder head from an ’82 fairmont that is currently at the machinist where it is being cleaned up and shaved down by .070”. I will be putting this on my original 200 ci that is already in the car, it’s in great shape and doesn’t need a rebuild-so why do it? I’ll put in a mild cam designed for torque, and some headers. And I have a T-5 from a ’95 S-10 and have confirmed it has the good gear ratio and that modern driveline can make a clutch for me and it will work. I’ve also got an 8” rear end from a Maverick that will go in with either 3.50 or 3.80 gears. (remember, big tires)

Where I am stuck, is with the carb choice and cam. For the cam, I have no idea-none. Hydrolic, solid lifters, all that crap, I just simply don’t have a clue what would work for my application.

With the carb, I’m kicking myself in the arse for not getting the carb that was on the Fairmont. I just remember seeing all those vacuum hoses, and coupled that with the thinking at the time that I wanted to really get a lot of power from my 250 ci that I was going to build, and I thought I would have no use for it.

So what I have as far as carbs, is the original Autolite 1100 that is on my 200, but it needs a rebuild (leaking when I shut the engine off), and I have the Carter RBS from the 1975 250 ci sitting in my garage and will definitely need a rebuild too.

So, what’s the best 1v carb to run? Keeping in mind that my head is the good log head from ’82 so it has a big ole carb opening. Should I rebuild my Carter, buy a different 1v, purchase a 2v and get an adapter, or have the 2v modified to directly accept a 2v?

Which, speaking of modifying the log head- no one in my area will do it, so who would I send it to an how much does it cost?

I know, I’m wordy, sorry.

Thanks for your advice in advance.