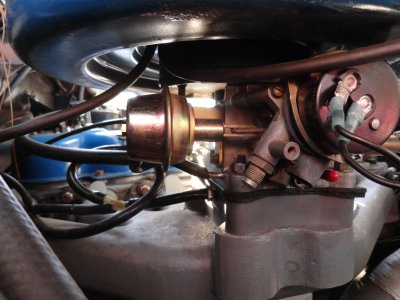

To begin with, I am absolutely happy with the Weber 38/38. There is no hesitation, it gets good economy (depending on my foot) and it starts and runs great at most temps and is smooth and easy to drive with.

What my issue is, that even with the slightest choke setting, the choke blades are too far closed and don’t open quick enough for smooth starts and idle. From cold, it will start, just like that, super smooth for a few seconds and then get lopey because the choke plates are not opening quick enough. This morning’s test, after not being driven for 3 days, was giving it two shots on the gas pedal and turning the key; bam it starts right up. I jumped out of the car and pushed the choke blades open and it maintained a perfectly smooth warm up. If I had not pushed the choke blades down manually, it would have had a very lopey idle until it got warm enough to remove the electric choke.

The choke spring needs a bit of tension to engage the high idle cam which engages the throttle shaft on the high idle perch but the choke blade tension is too stiff to be pulled down by vacuum. If the choke blades were fully removed it would actually be better.

Anyone with a similar experience and any tips? I may see what it’s like if I remove the blades for testing.

What my issue is, that even with the slightest choke setting, the choke blades are too far closed and don’t open quick enough for smooth starts and idle. From cold, it will start, just like that, super smooth for a few seconds and then get lopey because the choke plates are not opening quick enough. This morning’s test, after not being driven for 3 days, was giving it two shots on the gas pedal and turning the key; bam it starts right up. I jumped out of the car and pushed the choke blades open and it maintained a perfectly smooth warm up. If I had not pushed the choke blades down manually, it would have had a very lopey idle until it got warm enough to remove the electric choke.

The choke spring needs a bit of tension to engage the high idle cam which engages the throttle shaft on the high idle perch but the choke blade tension is too stiff to be pulled down by vacuum. If the choke blades were fully removed it would actually be better.

Anyone with a similar experience and any tips? I may see what it’s like if I remove the blades for testing.

Last edited: