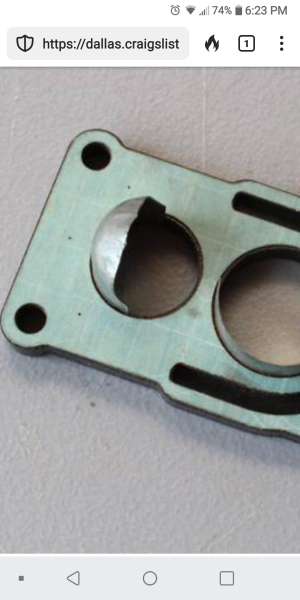

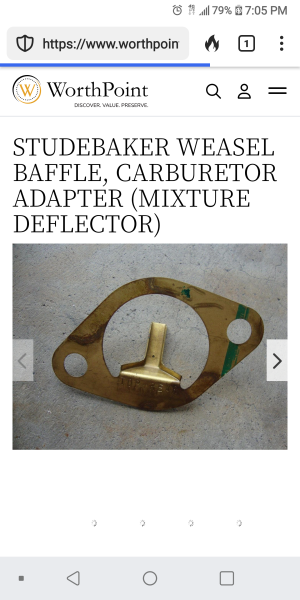

The OEMs used flow tabs in the carb to 'bend' flow towards lean areas, similar to sticking your finger tip into a stream of faucet water to alter flow direction. Apparently it works to some degree, as they all used it. I knew a Super Stock racer that used small sections of tubing bends (like the first photo but more extreme) to both direct flow and to keep fuel off the floor, and claimed it solved the majority of lean cylinder issues with the massive wet fueling. That was a Chevy I6 that did low 10s, and I still remember the radical cam making a steam locomotive beat at idle... chug, chug, chug. He said fuel distribution was his greatest single limiter.

Fuel distribution is a fact of life with long heads and single-point wet fueling, but whatever you can do to improve it is a good thing. Limiting over-carbing to maintain flow velocity is a first step. I've seen this done with progressive linkage and throttle limiters, so they only open enough for max power required flow and no more. Wet flow can be a tough hurdle.

Speaking of measuring cylinders, exhaust gas temperature (EGT) is inexpensive to use today, so if your application can benefit from cylinder balancing data, it's much more accessible. The specific readings are less important than comparative values for purposes of balancing.