You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Need a little input

- Thread starter Maketimber

- Start date

This relates to all small sixes

Thank you~

powerband: I recognize the 1st chart.

The 2nd I have not seen. It looks like a hi fire or modern coil below the words “tachometer"

What is that component on the 2nd schematics furtherest to the lower right w/red’n green wire?

powerband: I recognize the 1st chart.

The 2nd I have not seen. It looks like a hi fire or modern coil below the words “tachometer"

What is that component on the 2nd schematics furtherest to the lower right w/red’n green wire?

PSIG

Famous Member

Hmm. The second graphic I posted for the programmable control wiring is from Ford Motor Company Diagnostic Systems Department, TFI white paper dated March 13, 2002. I assume it would be accurate, but I'll check other references.Unfortunately I numbered the module from top to bottom as did gofastforless

chad: component on the 2nd schematics furtherest to the lower right w/red’n green wire?

.

.

red and green = B+(12V) and Module 'trigger' to hi energy TFI coil from later Fords'.

.

www.summitracing.com

.

www.summitracing.com

.

hav fub

.

.

.

red and green = B+(12V) and Module 'trigger' to hi energy TFI coil from later Fords'.

.

Free Shipping on Orders Over $109 at Summit Racing

Find Parts and Accessories tfi coil KEYWORD and get Free Shipping on Orders Over $109 at Summit Racing!

hav fub

.

No biggie- there's no "accurate or inaccurate", just reversed pin # reference. Us "shadetree" guys just numbered from the top, since numbering top to bottom and writing left to right is instinct. . . And if I may say so, logically it seems Ford would have numbered from the top too. There's no conflict with where the wires go, and that's the primary thing.Hmm. The second graphic I posted for the programmable control wiring is from Ford Motor Company Diagnostic Systems Department, TFI white paper dated March 13, 2002. I assume it would be accurate, but I'll check other references.

PSIG

Famous Member

OK, no problem if you have a diagram to look at.

If it helps others sometime, many (not all) connectors will have a tiny reference number molded-in at one or more pin locations. This is a crappy photo, but shows a TIF connector with a "1" by pin 1. Again, not on all, or could be by a random pin (4 or whatever) or back-side, or in the recess, just so instructions without images can be followed, usually in electrical testing. Likewise, they often have a tiny part number (or partial) molded-in to help find replacements. My eyes can't see them anymore without a lighted magnifier.

If it helps others sometime, many (not all) connectors will have a tiny reference number molded-in at one or more pin locations. This is a crappy photo, but shows a TIF connector with a "1" by pin 1. Again, not on all, or could be by a random pin (4 or whatever) or back-side, or in the recess, just so instructions without images can be followed, usually in electrical testing. Likewise, they often have a tiny part number (or partial) molded-in to help find replacements. My eyes can't see them anymore without a lighted magnifier.

ok, all this helps. I get now ‘use ford TFI w/hei 4 pin’ in this app. Now...

TFIs

*a full write up appeared on upgrades, who’s to buy, insides of several’n more

*over on "4 eyes” (site is ford cars ’79 - 86 and some up to ’92/3) site/32 forums (+ 18 subForums).

TFIs

*a full write up appeared on upgrades, who’s to buy, insides of several’n more

*over on "4 eyes” (site is ford cars ’79 - 86 and some up to ’92/3) site/32 forums (+ 18 subForums).

Thanks for that, means I've posted the order wrong. I can't see that either w/o help! LOL.OK, no problem if you have a diagram to look at.

If it helps others sometime, many (not all) connectors will have a tiny reference number molded-in at one or more pin locations. This is a crappy photo, but shows a TIF connector with a "1" by pin 1. Again, not on all, or could be by a random pin (4 or whatever) or back-side, or in the recess, just so instructions without images can be followed, usually in electrical testing. Likewise, they often have a tiny part number (or partial) molded-in to help find replacements. My eyes can't see them anymore without a lighted magnifier.

View attachment 19927

us 3 may have OES (old eye syndrome) LOL

I have worse: I wrenched asa kid (‘60s to '71or so), left it (long story but some was “had money’) and

did not come back till 21st century. This means I missed alot of automotive development (no more carbs, lots

of sensors, computer aditions, & plenty more). I have been catchin up thru all your (& bub's) kindness. I appreciate it.

The boss (a buddy) will all ways run the OBD Dx machine tho. If I keep @ it I may understand soon 8^ )

(I think I’ll go back to that TFI thread as I might have one on my ’85 fox waggy.)

I have worse: I wrenched asa kid (‘60s to '71or so), left it (long story but some was “had money’) and

did not come back till 21st century. This means I missed alot of automotive development (no more carbs, lots

of sensors, computer aditions, & plenty more). I have been catchin up thru all your (& bub's) kindness. I appreciate it.

The boss (a buddy) will all ways run the OBD Dx machine tho. If I keep @ it I may understand soon 8^ )

(I think I’ll go back to that TFI thread as I might have one on my ’85 fox waggy.)

PSIG

Famous Member

It's just been a slow progression of advancements across the decades. However, it can be a bit like a fire hose of info if you try to catch-up 50+ years all at once. A short review of progression over the years up through the '90s:did not come back till 21st century. This means I missed alot of automotive development (no more carbs, lots

of sensors, computer aditions, & plenty more). I have been catchin up thru all your (& bub's) kindness.

- Early 1900s: Kettering (points-switched power to an ignition coil to build energy and then discharge it at high voltage.

- 1900s to 1960s: Various minor improvements with mechanical advance for rpm changes and manual driver timing adjustment.

- Early 1960s: Big jump in control with vacuum advance to adjust for load changes. Effectively, mechanical "3D" timing.

- Mid-1960s: Dual-points and invention of solid-state CDI ignition (used in MSD soon). Both used primarily for high-rpm advantages.

- Early 1970s: Solid-state points switching replacement arrives. No more points! Ford introduces DuraSpark-II. MSD arrives.

- Mid-1970s: Electronic dwell control, enabling much stronger high-energy (HE) sparks. Used by GM (4-pin HEI) in everything.

- Late 1970s: Ford introduces DuraSpark-I high energy systems in CA emissions applications. Retains DS-II for 49-state Fed emissions.

- Early 1980s: Hobbyists creatively apply HEI modules and coils to get better sparks from points and DS-II.

- Mid-1980s: Ford moves to HE for more applications with electronic timing controlled TFI. No more weights, springs and canisters!

- Late 1980s: All OEMs move to electronic timing control (TFI, GM 7/8 pin, etc). The days of mechanical and vac advance are almost over.

- Early 1990s: Ford and GM move to distributorless coil packs for most applications. This, like TFI, requires electronic timing control.

- Late 1990s: Ford moves to COP (Coil On Plug) and GM to mixed CNP (Coil Near Plug) and COP per-cylinder coils. Distributors are gone.

Lots more activity 25 years ago, with the most substantial being the introduction of inexpensive wide-band oxygen sensors for home tuning, enabling and expanding electronic kits and systems to run and tune most any ignition and fuel injection at home or track. MegaSquirt arrived about then, changing the face of engine control options for hobbyists to serious racers.

Lots more activity 25 years ago, with the most substantial being the introduction of inexpensive wide-band oxygen sensors for home tuning, enabling and expanding electronic kits and systems to run and tune most any ignition and fuel injection at home or track. MegaSquirt arrived about then, changing the face of engine control options for hobbyists to serious racers.Like Starbucks, MS built the vast acceptance of carb-style tuning of EFI (on everything since the '80s) and permitted both more-advanced DIY tuning of factory systems and carb or distributor conversions. The mid-2000s see PC programs first appear to allow hobby-level advanced tuning with data analysis guidance from that handful of sensors. And similar to Starbucks 20+ years later, the market is now populated by many, many simple to complex systems from commercial kits to DIY and experimental stuff.

OK, you're caught-up. Whatcha doin' next?

You forgot magneto's, they were used in the 20's cars up to the 80's in race cars without a battery.It's just been a slow progression of advancements across the decades. However, it can be a bit like a fire hose of info if you try to catch-up 50+ years all at once. A short review of progression over the years up through the '90s:

Early 2000s - you came back.

- Early 1900s: Kettering (points-switched power to an ignition coil to build energy and then discharge it at high voltage.

- 1900s to 1960s: Various minor improvements with mechanical advance for rpm changes and manual driver timing adjustment.

- Early 1960s: Big jump in control with vacuum advance to adjust for load changes. Effectively, mechanical "3D" timing.

- Mid-1960s: Dual-points and invention of solid-state CDI ignition (used in MSD soon). Both used primarily for high-rpm advantages.

- Early 1970s: Solid-state points switching replacement arrives. No more points! Ford introduces DuraSpark-II. MSD arrives.

- Mid-1970s: Electronic dwell control, enabling much stronger high-energy (HE) sparks. Used by GM (4-pin HEI) in everything.

- Late 1970s: Ford introduces DuraSpark-I high energy systems in CA emissions applications. Retains DS-II for 49-state Fed emissions.

- Early 1980s: Hobbyists creatively apply HEI modules and coils to get better sparks from points and DS-II.

- Mid-1980s: Ford moves to HE for more applications with electronic timing controlled TFI. No more weights, springs and canisters!

- Late 1980s: All OEMs move to electronic timing control (TFI, GM 7/8 pin, etc). The days of mechanical and vac advance are almost over.

- Early 1990s: Ford and GM move to distributorless coil packs for most applications. This, like TFI, requires electronic timing control.

- Late 1990s: Ford moves to COP (Coil On Plug) and GM to mixed CNP (Coil Near Plug) and COP per-cylinder coils. Distributors are gone.

Lots more activity 25 years ago, with the most substantial being the introduction of inexpensive wide-band oxygen sensors for home tuning, enabling and expanding electronic kits and systems to run and tune most any ignition and fuel injection at home or track. MegaSquirt arrived about then, changing the face of engine control options for hobbyists to serious racers.

Like Starbucks, MS built the vast acceptance of carb-style tuning of EFI (on everything since the '80s) and permitted both more-advanced DIY tuning of factory systems and carb or distributor conversions. The mid-2000s see PC programs first appear to allow hobby-level advanced tuning with data analysis guidance from that handful of sensors. And similar to Starbucks 20+ years later, the market is now populated by many, many simple to complex systems from commercial kits to DIY and experimental stuff.

OK, you're caught-up. Whatcha doin' next?

Mr. Kettering, who developed breaker points, and the electric starter motor in 1912- his son followed in his engineering steps. Do you know what he is responsible for developing that had as much impact on transportation as his dad?It's just been a slow progression of advancements across the decades. However, it can be a bit like a fire hose of info if you try to catch-up 50+ years all at once. A short review of progression over the years up through the '90s:

Early 2000s - you came back.

- Early 1900s: Kettering (points-switched power to an ignition coil to build energy and then discharge it at high voltage.

- 1900s to 1960s: Various minor improvements with mechanical advance for rpm changes and manual driver timing adjustment.

- Early 1960s: Big jump in control with vacuum advance to adjust for load changes. Effectively, mechanical "3D" timing.

- Mid-1960s: Dual-points and invention of solid-state CDI ignition (used in MSD soon). Both used primarily for high-rpm advantages.

- Early 1970s: Solid-state points switching replacement arrives. No more points! Ford introduces DuraSpark-II. MSD arrives.

- Mid-1970s: Electronic dwell control, enabling much stronger high-energy (HE) sparks. Used by GM (4-pin HEI) in everything.

- Late 1970s: Ford introduces DuraSpark-I high energy systems in CA emissions applications. Retains DS-II for 49-state Fed emissions.

- Early 1980s: Hobbyists creatively apply HEI modules and coils to get better sparks from points and DS-II.

- Mid-1980s: Ford moves to HE for more applications with electronic timing controlled TFI. No more weights, springs and canisters!

- Late 1980s: All OEMs move to electronic timing control (TFI, GM 7/8 pin, etc). The days of mechanical and vac advance are almost over.

- Early 1990s: Ford and GM move to distributorless coil packs for most applications. This, like TFI, requires electronic timing control.

- Late 1990s: Ford moves to COP (Coil On Plug) and GM to mixed CNP (Coil Near Plug) and COP per-cylinder coils. Distributors are gone.

Lots more activity 25 years ago, with the most substantial being the introduction of inexpensive wide-band oxygen sensors for home tuning, enabling and expanding electronic kits and systems to run and tune most any ignition and fuel injection at home or track. MegaSquirt arrived about then, changing the face of engine control options for hobbyists to serious racers.

Like Starbucks, MS built the vast acceptance of carb-style tuning of EFI (on everything since the '80s) and permitted both more-advanced DIY tuning of factory systems and carb or distributor conversions. The mid-2000s see PC programs first appear to allow hobby-level advanced tuning with data analysis guidance from that handful of sensors. And similar to Starbucks 20+ years later, the market is now populated by many, many simple to complex systems from commercial kits to DIY and experimental stuff.

OK, you're caught-up. Whatcha doin' next?

A minor tweak: vacuum advance began in the '50's.

Continue to use the simple, effective and dependable mechanical systems of the '80's to fire the simple, balanced, durable century-old inline 6.OK, you're caught-up. Whatcha doin' next?

Oh, and I'm not "caught up". Was not behind.

Last edited:

last I B membahed mopor was tops w/their orange box,

nxt thing I knew - kids were ‘chipin' (I guess its called) all the Jap rigs w/their LapTop!

Kinda funny as I went thru same thing asa builder: do it as gramps & Dad to air hoses’n their guns on shingelin only to

advanced framing, science in building envelopes, hand-held guns through-out the trades...

In the middle was education, employment, ‘office’ work and steady income wrkin 4 others (no more cold garages, out door construction). Pretty fulfilling, safety 4 two growin girls, BUT... I guess I missed the more 'hands on' (no less creative tho).

nxt thing I knew - kids were ‘chipin' (I guess its called) all the Jap rigs w/their LapTop!

Kinda funny as I went thru same thing asa builder: do it as gramps & Dad to air hoses’n their guns on shingelin only to

advanced framing, science in building envelopes, hand-held guns through-out the trades...

In the middle was education, employment, ‘office’ work and steady income wrkin 4 others (no more cold garages, out door construction). Pretty fulfilling, safety 4 two growin girls, BUT... I guess I missed the more 'hands on' (no less creative tho).

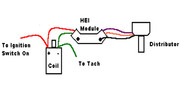

Any updates to this wiring diagram?A couple options for you, that have been mentioned:

First is points distributor with TFI module and TFI coil:

View attachment 19874

Next is either TFI or locked-advance DS distributors to a programmable ignition or full engine control, in this example Speeduino, but others are similar. With this, any coil, or even distributorless coil packs can be used, although the TFI coil is a good one. The controller settings are included, but ignore them for now:

View attachment 19875

The module wiring is nearly identical, but 2 wires to the controller, 1 to the coil. An example of an inexpensive kit to DIY assemble is the UA4C, with case, case end plates, pigtail harness and BlueTooth module if you want wireless tuning. The DS distributor is a VR system, so will also need a signal conditioner. While an even less expensive unit could be used, this one gives the option to do full EFI control if you decide to go that way in the future. Yes, it's a full EFI ECM, and we are only using the ignition control portion of it for this.

I hope to finish design and development of a complete and assembled (ready to install) programmable ignition controller available by summer, at a similar price or under $200.

Pin 4 still left open?

Grounding connections….anything special?

I’ll be wiring my 1968 points distributor to the TFi soon.

PSIG

Famous Member

Not sure what you're after for 'updates'? Pins are numbered 1-6 bottom-up (distributor mount), or left to right if horizontal with lock nub facing up. Mounting must be to a good heat sink surface with heat sink compound, and the factory remote mount is one option.

In-spite of several concerns for proper operation of cranking (Pin4 START dwell function) and running dwell (Pin6 PIP for running/adaptive dwell function) using the diagram wiring, it appears to 'work' by the diagram as a simple ignition coil driver, so... Based on Ford documents and factory wiring, my hunch is that it's running in high-dwell cranking mode without Pin4 input in RUN. With Pin6 static 12V and without PIP input (at least from the points and blinded by 12V) it's not likely using adaptive dwell, including the additive dwell during acceleration it's designed to do. But I'd have to verify those hunches with testing, and if it runs your engine well enough, and long enough, then hey - good enough. Check coil and module temperatures after some running in order to verify no heat issues.

Based on Ford documents and factory wiring, my hunch is that it's running in high-dwell cranking mode without Pin4 input in RUN. With Pin6 static 12V and without PIP input (at least from the points and blinded by 12V) it's not likely using adaptive dwell, including the additive dwell during acceleration it's designed to do. But I'd have to verify those hunches with testing, and if it runs your engine well enough, and long enough, then hey - good enough. Check coil and module temperatures after some running in order to verify no heat issues.

Ground is on Pin1 as in the diagram, and should be clean and protected (silicone grease) to the engine block/head as a critical connection.

In-spite of several concerns for proper operation of cranking (Pin4 START dwell function) and running dwell (Pin6 PIP for running/adaptive dwell function) using the diagram wiring, it appears to 'work' by the diagram as a simple ignition coil driver, so...

Ground is on Pin1 as in the diagram, and should be clean and protected (silicone grease) to the engine block/head as a critical connection.

So possibly no dwell control with TFI and points?

PSIG

Famous Member

Possibly no adaptive dwell control, but apparently it's within limits from the operating experience of others. This is only a hunch, based on Ford and other documentation, and theory of operation. I (just me) would require testing for any conclusions of what actually occurs, and if it's OK or a bad (or less than optimal) thing somehow. That said, it can't be bad or too bad in any case, as demonstrated by successful use by others, so … Point is, it may not be doing what you think it is/should, regardless of feelings about it. It appears to make a hot spark, and hasn't failed by stories, so go from there.

Last edited:

Will the TFI module work with all its features when used with a duraspark magnetic pickup? I've heard the TFI distributor switched to a hall effect type but that just may be a fancy name for the same thing not that familiar with these terms, though I've read that some of those trigger types give a sine wave vs a square wave. Would a different wave form confuse the module?

NO. Duraspark and HEI are magnetic sine wave signals, the TFI is "hall effect" ON/OFF signal. One can't read the other. Points work with TFI, as they make a sharp clean on/off signal.Will the TFI module work with all its features when used with a duraspark magnetic pickup?

Similar threads

All Small Six

New Adventures in electrics fans and inline 6’s

- Replies

- 74

- Views

- 7K

All Small Six

Newby looking for input on engine swap

- Replies

- 5

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 38

- Views

- 5K

- Replies

- 1

- Views

- 2K