CHCzecora

New member

Cooling Fans:

@TrickSix - After getting up in the space, it is pretty minimal there and I'm hesitant to go mechanical now (also taking note of @63 Sprint's note on potentially too much cooling in the deep cold). Another snowcatter mentioned double fans - adding a push fan. I'd like y'alls take on this, but it seems like it could be a fairly easy add on the outside of the radiator (@sixtseventwo4d would this need shrouding?). Max of 15 MPH doesn't bring in much air!

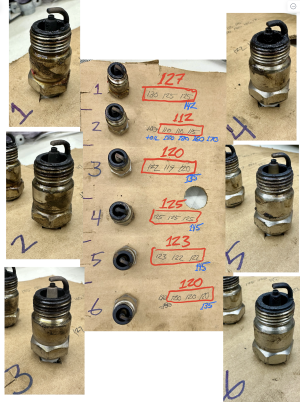

Pulled off the grill, here is the radiator:

Alternators:

@Frank - Thanks for the upvote on the 1-wire. I will reconsider! @sixtseventwo4d good call on checking/going with the bigger wire gauge.

Carburetor:

Seems like the consensus is stick with what I got. @Frank your reasoning sounds legit "low end and moderate rpm" is the overall use case.

RPMs:

@drag-200stang @DON - I'll have to look into this. Not sure how reliable or functional my instrumentation is at this point.

Timing Chain:

@63 Sprint - I wonder if this is a thing for this year... worth pursuing when I have the radiator off?

@TrickSix - After getting up in the space, it is pretty minimal there and I'm hesitant to go mechanical now (also taking note of @63 Sprint's note on potentially too much cooling in the deep cold). Another snowcatter mentioned double fans - adding a push fan. I'd like y'alls take on this, but it seems like it could be a fairly easy add on the outside of the radiator (@sixtseventwo4d would this need shrouding?). Max of 15 MPH doesn't bring in much air!

Pulled off the grill, here is the radiator:

Alternators:

@Frank - Thanks for the upvote on the 1-wire. I will reconsider! @sixtseventwo4d good call on checking/going with the bigger wire gauge.

Carburetor:

Seems like the consensus is stick with what I got. @Frank your reasoning sounds legit "low end and moderate rpm" is the overall use case.

RPMs:

@drag-200stang @DON - I'll have to look into this. Not sure how reliable or functional my instrumentation is at this point.

Timing Chain:

@63 Sprint - I wonder if this is a thing for this year... worth pursuing when I have the radiator off?