You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upgrade Points Distributor To Fire With A TFI Module

- Thread starter Frank

- Start date

I imagine the old copper core wires may still be available. I watched the guys on Roadkill Garage ruin 2 MSD boxes AND a HEI module in a few hundred mile road trip. Finally realized he had solid core plug wires. The noise did wipe out the MSD in a few hours, I was surprised. They were mounted inside the car too.do they make any that arent these daze?

I don't know what the plug wires are on the old Rambler, with TFI ignition it doesn't matter.

Solid copper wires will induce a high enough voltage in a parallel plug wire to create a spark in the wrong cylinder. Pre-ignition.I imagine the old copper core wires may still be available. I watched the guys on Roadkill Garage ruin 2 MSD boxes AND a HEI module in a few hundred mile road trip. Finally realized he had solid core plug wires. The noise did wipe out the MSD in a few hours, I was surprised. They were mounted inside the car too.

I don't know what the plug wires are on the old Rambler, with TFI ignition it doesn't matter.

We had that happen in one of our engines where we didn't realize the plug wires were solid. Almost lost the engine.

By the same token, any trigger wire that has to run any distance from a distributor with solid core plug wires to trigger an external module or unit will have a high voltage induced in it and will destroy the trigger circuitry despite the location of the unit.

The TFI module is no exception and may be more vulnerable since it has additional trigger circuitry to control dwell time.

The only saving grace of the TFI module is that it is not a high output device and creates a lot less of an electromagnetic field around the plug wires and the TFI trigger wire would have to be closer to the coil and plug wires to get damaged.

Last edited:

Really good to know! Thanks, knowledge gained.Solid copper wires will induce a high enough voltage in a parallel plug wire to create a spark in the wrong cylinder. Pre-ignition.

We had that happen in one of our engines where we didn't realize the plug wires were solid. Almost lost the engine.

By the same token, any trigger wire that has to run any distance from the distributor to trigger and external module or unit will have a high voltage induced in it and will destroy the trigger circuitry despite the location of the unit.

The TFI module is no exception and may be more vulnerable since it has additional trigger circuitry to control dwell time.

The only saving grace of the TFI module is that it is not a high output device and creates a lot less of an electromagnetic field around the plug wires and the TFI trigger wire would have to be closer to the coil and plug wires to get damaged.

gb500, that's a great question, and I should have addressed it already.Frank- did you keep the condenser on the points - or remove it when you added the tfi module?

Yes the condenser is still in service. Here's the story- have heard some advocate that it needs to be removed. And that sounds logical to me too. But on the Rambler (the one on this thread), I was so annoyed with the trouble to get to and work inside the dist, that once the module was in, and it ran well, I didn't remove the condenser. I have not opened the distributor cap since before the module.

As an aside, the module install was done because when I went to change points after buying the car, I could not get them set right, there's no direct line of sight plus the almost perpendicular angle. I got so PO'd I pulled the distributor out of the engine to get the points and everything else in there set right, and swore I was not going to change those points again.

On the '69 240 engine with factory points distributor, I removed the condenser when setting up the distributor/module system. It had an infrequent intermittent miss. Obvious it was a split-second ignition drop-out. Randomly, once every 3-5 minutes. I reinstalled the condenser and it has not done that since. I don't know if the condenser was the cure of itself, or perhaps something else was amiss. It quit missing when put back in, and, like the Rambler, I have not opened it up since.

Last edited:

Agree. And no change to the factory advance curves played a big role in my decision.I like the idea of keeping the points. If the electric boxes fail you can home on the points!

THE FRENCHTOWN FLYER

Top Poster

VIP

Subscriber

Supporter 2023

Supporter 2022

Supporter 2021

Supporter 2020

REDLINE 10K

Supporter 2018

Just like the wagon my parents had when I was a child. They took the family of six to Florida on a vacation in it once. How we survived is beyond me, but good memories nonetheless...BTW- that's 100% original in there. (Well, until I put that TFI in!) 1959 Rambler, 42,000 actual miles...

Thanks for the heads up about a points TFI setup.

standard 1st procedure in the day for more than this 1 M/M/Y.I pulled the distributor out of the engine to get the points and everything else in there set right

Rod Beauvex

Active member

Just though I drop this link here for the Velleman Ignition Kit, that works on the same principle, using the points as a switch. The nice thing about this kit is that you can set it up for six volt cars, though you may need to fully isolate it for hot ground vehicles.

As an interesting aside, Ford used to offer something similar for their bigger heavy duty engines in the sixties. Their brochures mention them.

As an interesting aside, Ford used to offer something similar for their bigger heavy duty engines in the sixties. Their brochures mention them.

Last edited:

Thank you for that input Rod!Just though I drop this link here for the Velleman Ignition Kit, that works on the same principle, using the points as a switch. The nice thing about this kit is that you can set it up for six volt cars, though you may need to fully isolate it for hot ground vehicles.

As an interesting aside, Ford used to offer something similar for their bigger heavy duty engines in the sixties. Their brochures mention them.

If you don’t mind re keying a distributor rotor, the GM module will also work with points, and they are available for a lower price. I’ve bought Delphi GM 4 pin modules from Amazon for under $30.

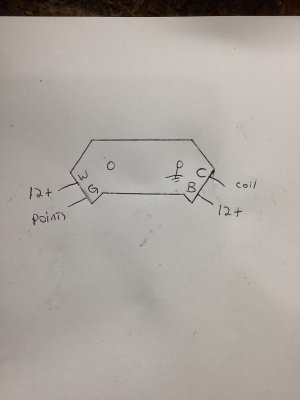

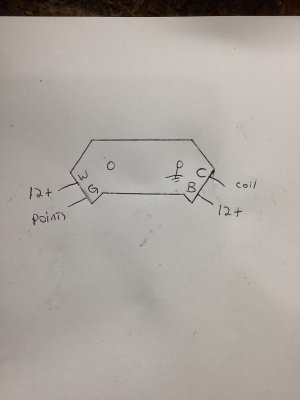

GM modules fire on points closing which requires the distributor rotor key to be removed and a 1/4 x 1/4 aluminum key mounted with a 6/32 screw. It’s nots very difficult to do. I’m currently running this on a 1968 240 with .045 plug gap.

GM modules fire on points closing which requires the distributor rotor key to be removed and a 1/4 x 1/4 aluminum key mounted with a 6/32 screw. It’s nots very difficult to do. I’m currently running this on a 1968 240 with .045 plug gap.

As an add on to using points and something I've encountered over the years and even more often as of recent; ohm test the points both open and closed. Many times they don't make the best contact, even new. Check to pos side independently, from terminal to contact and then the contact to the mounting of the ground side. Be sure to open and close several times when finally checking closed continuity. I have several sets of new ones that just won't pass snuff.

Even now because of Houston's humidity, I still need to drag a business card in between from time to time.

Even now because of Houston's humidity, I still need to drag a business card in between from time to time.

good “ele info" @

also

also

philford

Famous Member

I have an old module at home I believe it has a flat grey cable with 3 wires and probably from the early 70's or so ..I think it was created at a time when it was an advancement to go from the traditional point gap to electrinic ignition, but before electronic ignition systems were so advanced.

as I recall the box has 3 wires but I never saw it installed. its a gold colored anodized alunimum box with heat sinks.. some may remember them being a common upgrade in about 1970 or so.

Im not sure how it affected the dwell I believe the dwell was affected by how close the points were set to the lobes, closer meant more dwell, I dont know if the module even tracked the close time or if it only worked upon the opening time of the points. a lot of old tune up kits came with a timing light and a dwell meter.

I assume the box likely takes away the load or spark generated at the point gap perhaps reducing the need to service and file or replace the points.at least so frequently.

normally when the points open up, I believe thats when the spark is generated in the primary coil. and the dwell I never understood so well. but obviously there is a relationship between dwell and timing. I think as the point gap increases it means its riding closer to the lobes and so dwell would also be increased,

maybe its just a more accurate way of adjusting the point gap? others here could elaborate or describe those details better than I , Im sure.

I wondered if an old box similar to this might help in some cases . as some may want to use a stock distributor and its advance, and also benefit from electronic ignition.

in my van it uses the ECU and it communicates with the knock sensor and it has the ability for the ECU to change the timing and that was an advancement in technology.

I have an old volvo from 66 and I put a distributor and spark box from a 74 volvo it fit fine but the distributor is alunimum where the original had a cast iron distribiutor and the 74 also had a vacuum retard. that one has a rotating bit with 4 flags and a reed sensor. it must fire the coil every 1/2 rev , thne the distributor rotor and cap channels the spark to the appropriate lead.

I was abl to flip it over to work as an additional advance and it somehow worked out.. perhaps I had some good luck.. I just set it up by trial and error..

its been running for 30 years now without any adjustment.. no pinking, starts fine.. I can;t see reason to ttry to improve it.

before that I was continuosly replacing burned up points and capactiors and the readjusting the timing was a lot of trouble. the motor is built from a mix of parts so I coudn't rely on OEM timing.

Its likely possible to use this spark box wiht an OEM distributior and why I might do that is to better reflect original appearance. I havent been so fussy, but many strive to make every part as OEM as possible.

I stuck the spark box up under the dash and no one notices it anyway.

I could see why some might choose to keep their original distributor and hide a similar functioning spark box , if they care about OEM appearance.

as I recall the box has 3 wires but I never saw it installed. its a gold colored anodized alunimum box with heat sinks.. some may remember them being a common upgrade in about 1970 or so.

Im not sure how it affected the dwell I believe the dwell was affected by how close the points were set to the lobes, closer meant more dwell, I dont know if the module even tracked the close time or if it only worked upon the opening time of the points. a lot of old tune up kits came with a timing light and a dwell meter.

I assume the box likely takes away the load or spark generated at the point gap perhaps reducing the need to service and file or replace the points.at least so frequently.

normally when the points open up, I believe thats when the spark is generated in the primary coil. and the dwell I never understood so well. but obviously there is a relationship between dwell and timing. I think as the point gap increases it means its riding closer to the lobes and so dwell would also be increased,

maybe its just a more accurate way of adjusting the point gap? others here could elaborate or describe those details better than I , Im sure.

I wondered if an old box similar to this might help in some cases . as some may want to use a stock distributor and its advance, and also benefit from electronic ignition.

in my van it uses the ECU and it communicates with the knock sensor and it has the ability for the ECU to change the timing and that was an advancement in technology.

I have an old volvo from 66 and I put a distributor and spark box from a 74 volvo it fit fine but the distributor is alunimum where the original had a cast iron distribiutor and the 74 also had a vacuum retard. that one has a rotating bit with 4 flags and a reed sensor. it must fire the coil every 1/2 rev , thne the distributor rotor and cap channels the spark to the appropriate lead.

I was abl to flip it over to work as an additional advance and it somehow worked out.. perhaps I had some good luck.. I just set it up by trial and error..

its been running for 30 years now without any adjustment.. no pinking, starts fine.. I can;t see reason to ttry to improve it.

before that I was continuosly replacing burned up points and capactiors and the readjusting the timing was a lot of trouble. the motor is built from a mix of parts so I coudn't rely on OEM timing.

Its likely possible to use this spark box wiht an OEM distributior and why I might do that is to better reflect original appearance. I havent been so fussy, but many strive to make every part as OEM as possible.

I stuck the spark box up under the dash and no one notices it anyway.

I could see why some might choose to keep their original distributor and hide a similar functioning spark box , if they care about OEM appearance.

Rod Beauvex

Active member

I was under the impression the purpose of the big cap was to reduce spark jump inside the cap from the more powerful spark from the electronic ignition systems.

philford

Famous Member

it looks like his new ( international ) cap has brass posts, and the one he's removing has the aliminum ones.

I think either will function but I prefer to pay a bit extra if I can get the brass type, and if I have it off Ill give the contacts a little scrape with a pointy knife to remove the buildup. after time the posts do get eaten up and the cap needs replacing. I'll usually wash it with a small clean brush and a little alcohol.

im not sure about htis distributor in particular but ofthen thee is a o-ring that helps the crankcase pressure from venting up through the distributor's shaft busings. if you have one apart maybe think of replacing it.. oil and vapors may cause issues with carbon tracking or cause issues with wire insulation. contacts etc. you probably have to extract the pin in tis shaft to get the gear off, to get it apart. Id mark how it came apart to avoid confusion. dont try to put the gear on 180 degrees out of phase, instead keep proper orientation of the pin, that pin may look like it fits either way bit it shoudl go back in the same orentation or the pin may not actually fit properly. yes you could install it with the gear out of phase and corrent that by moving the wires.

if its a tapered pin , keep the same orientation of the pin as well.

personally Id take a file or a punch and make a small but visible little mark so I'm not confused later. pen ink or paint is too easily washed off id also take a fine file and remove any burrs before pulling that through the bushing.

it likely has a brass bushing for the shaft so I'd clean and oil it.

its probably nt necessary to take a distributor apart ften but maybe after time, it wont hurt to and to make sure the weights can move properly.

that return spring is impotant , i know that certain distributors may call for a different spring weight for certain applications. the tension of the spring or any looseness will affect timing advance . you might inspect the hooks of the spring and possibly see some wear on the spring itself, also you can;t see any fatige but the spring could change in tension over many years.

maybe its possible to renew the OEM springs. ultimately the advance could be graphed with better equipment than most of us will have at home.

Maybe a ford manual would give some different spring part niumbers for different applications if there are choices of springs? I don't think one could identify them or their differences, very easily otherwise.

possibly that is important when transplanting different distributors? or are they all the same spring?

I think either will function but I prefer to pay a bit extra if I can get the brass type, and if I have it off Ill give the contacts a little scrape with a pointy knife to remove the buildup. after time the posts do get eaten up and the cap needs replacing. I'll usually wash it with a small clean brush and a little alcohol.

im not sure about htis distributor in particular but ofthen thee is a o-ring that helps the crankcase pressure from venting up through the distributor's shaft busings. if you have one apart maybe think of replacing it.. oil and vapors may cause issues with carbon tracking or cause issues with wire insulation. contacts etc. you probably have to extract the pin in tis shaft to get the gear off, to get it apart. Id mark how it came apart to avoid confusion. dont try to put the gear on 180 degrees out of phase, instead keep proper orientation of the pin, that pin may look like it fits either way bit it shoudl go back in the same orentation or the pin may not actually fit properly. yes you could install it with the gear out of phase and corrent that by moving the wires.

if its a tapered pin , keep the same orientation of the pin as well.

personally Id take a file or a punch and make a small but visible little mark so I'm not confused later. pen ink or paint is too easily washed off id also take a fine file and remove any burrs before pulling that through the bushing.

it likely has a brass bushing for the shaft so I'd clean and oil it.

its probably nt necessary to take a distributor apart ften but maybe after time, it wont hurt to and to make sure the weights can move properly.

that return spring is impotant , i know that certain distributors may call for a different spring weight for certain applications. the tension of the spring or any looseness will affect timing advance . you might inspect the hooks of the spring and possibly see some wear on the spring itself, also you can;t see any fatige but the spring could change in tension over many years.

maybe its possible to renew the OEM springs. ultimately the advance could be graphed with better equipment than most of us will have at home.

Maybe a ford manual would give some different spring part niumbers for different applications if there are choices of springs? I don't think one could identify them or their differences, very easily otherwise.

possibly that is important when transplanting different distributors? or are they all the same spring?

Last edited:

Similar threads

- Replies

- 1

- Views

- 185

All Small Six

Starting new build

- Replies

- 114

- Views

- 9K

All Small Six

Is a Distributor For a 200 Xflow Possible?

- Replies

- 8

- Views

- 3K

All Small Six

New Adventures in electrics fans and inline 6’s

- Replies

- 74

- Views

- 7K

- Replies

- 16

- Views

- 4K