You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

240ci Suggestions: 240 Pistons, Thin Metric Rings, and...

- Thread starter GreasyNRusty

- Start date

This only applies to 240ci engines

GreasyNRusty

Well-known member

P-

I might as well admit defeat on the 240/4.9L swap on this one; I can see it turning in to (yet another) huge money black hole.

If I can buy the truck cheep, simply regearing to a 3.07 (from my '91), a cat-back exhaust, and lightening the poor thing as much as possible whilst retaining the OEM 300 seems the only way forward possible. (Sniff-snivel-whine-moan ).

).

Thanks for your help!

eddiE

(PS-You do psycho evaluation in yer "spare" time?)

I might as well admit defeat on the 240/4.9L swap on this one; I can see it turning in to (yet another) huge money black hole.

If I can buy the truck cheep, simply regearing to a 3.07 (from my '91), a cat-back exhaust, and lightening the poor thing as much as possible whilst retaining the OEM 300 seems the only way forward possible. (Sniff-snivel-whine-moan

Thanks for your help!

eddiE

(PS-You do psycho evaluation in yer "spare" time?)

Last edited:

I'm in therapy myself after 11,000 posts on this forum.(PS-You do psycho evaluation in yer "spare" time?)

It's looking like my chances of recovery are slim to none.

Last edited:

Maybe after you get the truck on the road and find out for sure what emissions testing it needs (If any) we can revisit this again.P-

I might as well admit defeat on the 240/4.9L swap on this one; I can see it turning in to (yet another) huge money black hole.

If I can buy the truck cheep, simply regearing to a 3.07 (from my '91), a cat-back exhaust, and lightening the poor thing as much as possible whilst retaining the OEM 300 seems the only way forward possible. (Sniff-snivel-whine-moan).

Thanks for your help!

eddiE

(PS-You do psycho evaluation in yer "spare" time?)

I don't believe in defeat.

GreasyNRusty

Well-known member

Neither do I; but I'm pragmatist enuff to go to Plan B if necessary. You can be rest-assured that the 3.9L (240 EFI) idear is still a-brewin' in the back of what little "mind" I have left.

You've gotten me really curious about the EFI valve/combustion chamber shrouded fast-burn design...I think the EFI head's designer paid close attention to Harry Weslake's patents and English Austin/BMC's usage in their log-running A-Series (and B-series), and if so, David Vizard may have some valuable input.

I opened up FordSix tonight with idea of posting a "Wanted" classified ad; see if I can get a crack-free head off one the members. Give me something to fool with during our cold, cruel, dark "Winter" (it was 80 and sunny today)(I went running in shorts; the paparazzi followed; watch the upcoming cover of National Enquirer).

today)(I went running in shorts; the paparazzi followed; watch the upcoming cover of National Enquirer).

Eddie

You've gotten me really curious about the EFI valve/combustion chamber shrouded fast-burn design...I think the EFI head's designer paid close attention to Harry Weslake's patents and English Austin/BMC's usage in their log-running A-Series (and B-series), and if so, David Vizard may have some valuable input.

I opened up FordSix tonight with idea of posting a "Wanted" classified ad; see if I can get a crack-free head off one the members. Give me something to fool with during our cold, cruel, dark "Winter" (it was 80 and sunny

Eddie

2 tidbits. Lots of fraud out there on parts off of forums and market place etc... That said be sure to establish a saved search on market place. I picked up an entire engine for $50 to mock up my engine mounts and I've seen lots of engines and parts for sale for reasonable amounts.

GreasyNRusty

Well-known member

Oh yeah; I bought an appropriate head offa Ted (Fordman75) awhile back. Long, long ago. Say, 2000-ish...Dinosaurs walked the Earth; Politicians told the truth...NO, NOT THAT FAR BACK! That said, I'd rather help out a member if possible but I reviewed Promaxx's website at No O'clock this morning and:

1. ProMaxx has a fairly decent image of the combustion chamber side of their replacement head; I can guesstimate what I need to do.

2. For the money, they have a fair price, and they make their head out of good cast iron, not that "other" metal;

3. According to what I've read on FordSix, they've fixed the durability problem (and yeah, I've got your posts in my sights...along with the 11,000+ post addict [above}...heh-heh);

4. Assuming I am able to talk the guy out of this truck, I've buy the solid foundation to begin with, i.e., the new head.

5. Thus, I am withdrawing my want ad, BUT NOT BECUZ I'M SKEERED; NO, not me. Not at all. EEK!

Eddie

1. ProMaxx has a fairly decent image of the combustion chamber side of their replacement head; I can guesstimate what I need to do.

2. For the money, they have a fair price, and they make their head out of good cast iron, not that "other" metal;

3. According to what I've read on FordSix, they've fixed the durability problem (and yeah, I've got your posts in my sights...along with the 11,000+ post addict [above}...heh-heh);

4. Assuming I am able to talk the guy out of this truck, I've buy the solid foundation to begin with, i.e., the new head.

5. Thus, I am withdrawing my want ad, BUT NOT BECUZ I'M SKEERED; NO, not me. Not at all. EEK!

Eddie

Last edited:

Good choice on the Promax replacement head.

It has hard seat inserts for both the intake and exhaust.

Depending on the camshaft valve lift you may want to buy the bare head and install the longer pre-EFI valves. 4.810" versus 4.750"

It has hard seat inserts for both the intake and exhaust.

Depending on the camshaft valve lift you may want to buy the bare head and install the longer pre-EFI valves. 4.810" versus 4.750"

GreasyNRusty

Well-known member

Paul, you have only yerself to blame for the P-Maxx head choice (well, you and your fellow enabler [above]): Your earlier suggestion in THIS THREAD last weekend, remember? Sheesh, I'm the ol' fart that is supposed to have CRS.

(Aside) Seen the Hat/Bumper Sticker/T-Shirt? "At my age, getting lucky means I remember why I'm here..."

To my way of thinking, cast iron is the better, stiffer material for a long, long inline engine with a non-skirted block.

Good suggestion on bare head, since whatever I do will get a sharp multiangle valve/seat job, probably on OE diameter nailheads. Diameter OK for a dump truck 300, i.e., adequate for a 240. I'll figure gas flow when I have a chance to do some cipherin'; THERM 101 was a long time andmany er, 2 beers ago.

Outstanding questions I have 'bout the P-Maxx replacement head:

1. Valve seat angles. I'm (here it comes, folks) "assuming" P-Maxx is using a single (30 or 45) angle;

2. General as-cast finish on the ports and combustion chamber;

3. I forgot...

I imagine those questions have all been asked and answered with pics, but...CRS. Good all-purpose excuse.

Further backwards FordSix reviewing at Zero-no-hundred Fried Day morning, during which I will ID all the various culprits, heh-heh. And then promptly fergit 'em.

Eddie

(Aside) Seen the Hat/Bumper Sticker/T-Shirt? "At my age, getting lucky means I remember why I'm here..."

To my way of thinking, cast iron is the better, stiffer material for a long, long inline engine with a non-skirted block.

Good suggestion on bare head, since whatever I do will get a sharp multiangle valve/seat job, probably on OE diameter nailheads. Diameter OK for a dump truck 300, i.e., adequate for a 240. I'll figure gas flow when I have a chance to do some cipherin'; THERM 101 was a long time and

Outstanding questions I have 'bout the P-Maxx replacement head:

1. Valve seat angles. I'm (here it comes, folks) "assuming" P-Maxx is using a single (30 or 45) angle;

2. General as-cast finish on the ports and combustion chamber;

3. I forgot...

I imagine those questions have all been asked and answered with pics, but...CRS. Good all-purpose excuse.

Further backwards FordSix reviewing at Zero-no-hundred Fried Day morning, during which I will ID all the various culprits, heh-heh. And then promptly fergit 'em.

Eddie

Last edited:

Single 45Outstanding questions I have 'bout the P-Maxx replacement head:

1. Valve seat angles. I'm (here it comes, folks) "assuming" P-Maxx is using a single (30 or 45) angle;

Much better than the couple of OEM heads I have seen. Not perfect by any means.2. General as-cast finish on the ports and combustion chamber;

Wait what was I saying....3. I forgot...

I did an eval. https://fordsix.com/threads/porting-a-promaxx-head.87440/page-2, post 39I imagine those questions have all been asked and answered with pics, but...CRS. Good all-purpose excuse.

I have other pics somewhere but the takeaway is the my Promaxx head had far less casting flash and smother transitions.

GreasyNRusty

Well-known member

I think (sometimes a dangerous thing and ALWAYS expensive) that I may have read through that WHOLE thread this A.M--As in, "Owww. I can't believe I ate the whole thing!" My brain was full, I tell ya, and for a double whammy, I...went to sleep... Then I got up'n'shaved 'n' saw m'self in the mirror, and A.), said, "Hoo, boy, would ya look at the head on that," and B.), Cackled and said, "ALL RIGHT! I WOKE UP!" (So to speak).

Had nightmares, though--Clouds of heavier-than-air (?) cast iron filings chased me around a world fulla cars with V-6 engines mounted crossthreaded and powering the wheels at the wrong end of the car...and Sydney Sweeny was always outta reach...(sniff)...

I'll make sure to reread #39 (or read it for the 1st time), THANX!

Eddie

Had nightmares, though--Clouds of heavier-than-air (?) cast iron filings chased me around a world fulla cars with V-6 engines mounted crossthreaded and powering the wheels at the wrong end of the car...and Sydney Sweeny was always outta reach...(sniff)...

I'll make sure to reread #39 (or read it for the 1st time), THANX!

Eddie

GreasyNRusty

Well-known member

WOW!

I'll just shut up now and go away and study that whole thread through several times...just wow.

Eddie

I'll just shut up now and go away and study that whole thread through several times...just wow.

Eddie

Careful that thread is about learning more than what to do especially early on.WOW!

I'll just shut up now and go away and study that whole thread through several times...just wow.

Eddie

GreasyNRusty

Well-known member

Misquoting Somebody who was REEL SMART and (apocryphally) once said, "Stoopidity is the inability to learn from mistakes."

I say, "Better you than me ." Nah, thanks for the head's-up; I shall try reel hard not to make 'em over... (doubtful).

." Nah, thanks for the head's-up; I shall try reel hard not to make 'em over... (doubtful).

I'm procrastinating a blower snoot rebuild now and again (mis)quoting Somebody else, "God help us one and all"; (those misadventures be over in the proper Forum, Mr. Moderator AI Sir).

"Zanax, gas or viagra, no one rides for free...... If this vans a rocking the seizure meds are in the glove box" (Snicker)

eddiE

I say, "Better you than me

I'm procrastinating a blower snoot rebuild now and again (mis)quoting Somebody else, "God help us one and all"; (those misadventures be over in the proper Forum, Mr. Moderator AI Sir).

"Zanax, gas or viagra, no one rides for free...... If this vans a rocking the seizure meds are in the glove box" (Snicker)

eddiE

Last edited:

GreasyNRusty

Well-known member

W:

My apologies; I'm sorry. I can be a smarta$$, er, "smartalec" without thinking. I just read your "Scammed" post https://fordsix.com/threads/scam-yes-i-fell-for-it.91195/#post-733994 in another Forum.

Meet me tomorrow night at "Big's" on Wilcrest Ave. here in beautiful, uptown Alief get-down Texas; I'm buyin'.

Eddie

My apologies; I'm sorry. I can be a smarta$$, er, "smartalec" without thinking. I just read your "Scammed" post https://fordsix.com/threads/scam-yes-i-fell-for-it.91195/#post-733994 in another Forum.

Meet me tomorrow night at "Big's" on Wilcrest Ave. here in beautiful, uptown Alief get-down Texas; I'm buyin'.

Eddie

That's a hump. No apologies necessary. I'm not easily offended.W:

My apologies; I'm sorry. I can be a smarta$$, er, "smartalec" without thinking. I just read your "Scammed" post https://fordsix.com/threads/scam-yes-i-fell-for-it.91195/#post-733994 in another Forum.

Meet me tomorrow night at "Big's" on Wilcrest Ave. here in beautiful, uptown Alief get-down Texas; I'm buyin'.

Eddie

GreasyNRusty

Well-known member

Gettin' kinda off the subject of piston rings here, but I'll tie it together. Maybe.

I read https://fordsix.com/threads/porting-a-promaxx-head.87440/ up to pg. 10, post 200 today. And kept re-reading 'til I realized my brain was full.

I can't offer any hard data, but:

Holy High-CR Heart-Shaped Historicity (Batman)

The heart-shaped combustion chamber of the British Austin/BMC/British Leyland “A”-Series engine had at least a peripheral influence on various Ford engines redesigned in the mid-‘80s; among the Ford engines was the Ford 300-6 EFI, known as the 4.9L. Check out these pics (BNC, top; Ford, bottom).

The heart-shaped combustion chamber was designed by Harry Weslake in the ‘30’s or during WWII, and was used from the outset of the A-Series from the outset to the end-of-production in 1990—a production spread of 52 years. Why? “…High torque, good economy…”

I’m also assuming: “Low emissions” and “ability to burn lowest-grade gasoline” with its low surface-to-volume fast-burn characteristics, and, since the Weslake patent (Patent info: ) is already out there, thus saving engineering time and the Austin engine already had a proven 50+ year track record, thus saving proving time… (Loosely, very loosely, summarized from The A-Series Engine: It’s First 60 Years) .

I’d like to summarize (“bowdlerize”, is probably a better word) again some excerpts from David Vizard’s book, Tuning the A-Series Engine (3rd Edition, ©1999) first published in 1985; think where the 4.9 head was in the design process), pages 231-232:

Heads for Economy

Extensive dyno testing…has indicated that three factors affect (sic) economy: the roughness of the intake port, the CR and flow capability of the exhaust port.

Many companies in the cylinder head business find it difficult to sell cylinder heads unless they have a fine, polished finish. These polished ports…contribute nothing [and] I concluded that the polished ports may be adversely affecting economy.

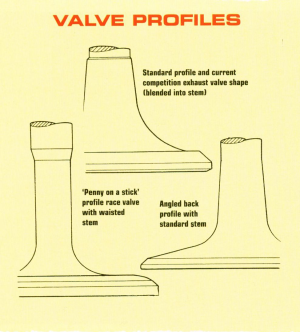

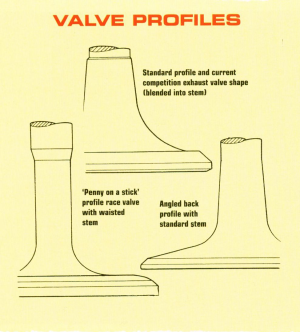

Eventually it was found that the best economy figures were achieved when the intake port was left virtually standard. The intake valve itself was back-cut and the face of the valve machined to leave a sharp edge so as to reduce the effect of backflow.

On the exhaust side, the valve diameter was increased from a 1.516 inch to 1.215 inch…

Here, the exhaust p ort valve and the exhaust port were tailored for high flow capability. In fact, put in simple terms, the exhaust port was given race engine treatment. Under these conditions, this cylinder head produced a 2% improvement in the steady speed fuel consumption between 30 and 70 mph.

At the time of this writing, my suggested formula for success in terms of economy from the head is to utilize absolutely standard intake port with a standard size intake valve, preferably of the Rimflo design. This should be used together with a larger Rimflo exhaust valve in a fully reworked exhaust port. The combustion chamber itself needs to be polished, as this will achieve two things. Firstly, it will cut down the surface area presented to the flame and therefore less heat will he conducted to the water jacket; secondly, the polished surface will also cause some of the heat to be reflected back into the chamber rather than conducted away. Remember, heat loss is also economy loss. We are burning the fuel to expand the air in the cylinder and the higher temperatures that ae achieved for a given amount of fuel, the more economy the engine will achieve.

RIMFLO

The quoted passage is basically 30 years old, possibly closer to 50, but I still think it has some applicability to the 4.9L (itself released for MY 1987).

For my usage, OEM-width intake, possibly but not probably, larger exhaust valves, necked-down stems, multiangle valve job, port and bowl cleanup, and HTB coating on combustion chamber and CC-side valve on a P-Max head might work and long-branch headers would work for MPG. Maybe work on a 240. See, I told ya I'd tie in a 240 short-block with thin-section low-tension rings together...

Eddie

REFERENCES

A. TEXT

1. The A-Series Engine: It’s First Sixty Years, Graham Robson. Haynes Publishing, 1st Edition, 2011.

2. Tuning the A-Series Engine, David Vizard. Haynes Publishing, 3rd Edition, 1998 First published in 1985.

B. IMAGES

1. A-Series Combustion Chamber https: //www.longspeed.com/fast-road-a-series-engines/

2. Ford 4.9L Combustion Chamber https://promaxxperformance.com/product/ford-300-fi-new-full/

3. Rimflo Valve https://www.calverst.com/technical-info/suitability-basics/

I read https://fordsix.com/threads/porting-a-promaxx-head.87440/ up to pg. 10, post 200 today. And kept re-reading 'til I realized my brain was full.

I can't offer any hard data, but:

Holy High-CR Heart-Shaped Historicity (Batman)

The heart-shaped combustion chamber of the British Austin/BMC/British Leyland “A”-Series engine had at least a peripheral influence on various Ford engines redesigned in the mid-‘80s; among the Ford engines was the Ford 300-6 EFI, known as the 4.9L. Check out these pics (BNC, top; Ford, bottom).

The heart-shaped combustion chamber was designed by Harry Weslake in the ‘30’s or during WWII, and was used from the outset of the A-Series from the outset to the end-of-production in 1990—a production spread of 52 years. Why? “…High torque, good economy…”

I’m also assuming: “Low emissions” and “ability to burn lowest-grade gasoline” with its low surface-to-volume fast-burn characteristics, and, since the Weslake patent (Patent info: ) is already out there, thus saving engineering time and the Austin engine already had a proven 50+ year track record, thus saving proving time… (Loosely, very loosely, summarized from The A-Series Engine: It’s First 60 Years) .

I’d like to summarize (“bowdlerize”, is probably a better word) again some excerpts from David Vizard’s book, Tuning the A-Series Engine (3rd Edition, ©1999) first published in 1985; think where the 4.9 head was in the design process), pages 231-232:

Heads for Economy

Extensive dyno testing…has indicated that three factors affect (sic) economy: the roughness of the intake port, the CR and flow capability of the exhaust port.

Many companies in the cylinder head business find it difficult to sell cylinder heads unless they have a fine, polished finish. These polished ports…contribute nothing [and] I concluded that the polished ports may be adversely affecting economy.

Eventually it was found that the best economy figures were achieved when the intake port was left virtually standard. The intake valve itself was back-cut and the face of the valve machined to leave a sharp edge so as to reduce the effect of backflow.

On the exhaust side, the valve diameter was increased from a 1.516 inch to 1.215 inch…

Here, the exhaust p ort valve and the exhaust port were tailored for high flow capability. In fact, put in simple terms, the exhaust port was given race engine treatment. Under these conditions, this cylinder head produced a 2% improvement in the steady speed fuel consumption between 30 and 70 mph.

At the time of this writing, my suggested formula for success in terms of economy from the head is to utilize absolutely standard intake port with a standard size intake valve, preferably of the Rimflo design. This should be used together with a larger Rimflo exhaust valve in a fully reworked exhaust port. The combustion chamber itself needs to be polished, as this will achieve two things. Firstly, it will cut down the surface area presented to the flame and therefore less heat will he conducted to the water jacket; secondly, the polished surface will also cause some of the heat to be reflected back into the chamber rather than conducted away. Remember, heat loss is also economy loss. We are burning the fuel to expand the air in the cylinder and the higher temperatures that ae achieved for a given amount of fuel, the more economy the engine will achieve.

RIMFLO

The quoted passage is basically 30 years old, possibly closer to 50, but I still think it has some applicability to the 4.9L (itself released for MY 1987).

For my usage, OEM-width intake, possibly but not probably, larger exhaust valves, necked-down stems, multiangle valve job, port and bowl cleanup, and HTB coating on combustion chamber and CC-side valve on a P-Max head might work and long-branch headers would work for MPG. Maybe work on a 240. See, I told ya I'd tie in a 240 short-block with thin-section low-tension rings together...

Eddie

REFERENCES

A. TEXT

1. The A-Series Engine: It’s First Sixty Years, Graham Robson. Haynes Publishing, 1st Edition, 2011.

2. Tuning the A-Series Engine, David Vizard. Haynes Publishing, 3rd Edition, 1998 First published in 1985.

B. IMAGES

1. A-Series Combustion Chamber https: //www.longspeed.com/fast-road-a-series-engines/

2. Ford 4.9L Combustion Chamber https://promaxxperformance.com/product/ford-300-fi-new-full/

3. Rimflo Valve https://www.calverst.com/technical-info/suitability-basics/

Last edited:

Referencing post 18:

anything before 96 isn't OBD II and does not require it to be plugged into for inspection.

Any vehicle over 25 years old is no longer subject to emissions testing in Harris County.

Texas has now done away with vehicle safety inspections so if your vehicle is over 25 years old you only deal with the DMV for licensing and registration. they did not skip the inspection fee though; you still get the gloved finger wave. Causes me to remember the old public pay phones when any passerby might check for forgotten change.

anything before 96 isn't OBD II and does not require it to be plugged into for inspection.

Any vehicle over 25 years old is no longer subject to emissions testing in Harris County.

Texas has now done away with vehicle safety inspections so if your vehicle is over 25 years old you only deal with the DMV for licensing and registration. they did not skip the inspection fee though; you still get the gloved finger wave. Causes me to remember the old public pay phones when any passerby might check for forgotten change.

GreasyNRusty

Well-known member

"Anything before 96 isn't OBD II and does not require it to be plugged into for inspection."

I bet they want to look for the dreaded Service Engine Soon light, though; or do OBD-I vehicles have a MIL?

"Any vehicle over 25 years old is no longer subject to emissions testing in Harris County."

FURREAL?! THIS IS INDEED GOOD NEWS!!!!!!!!!!

The "buy-the-neighbor's-truck" plot just got kicked into Warp 11!

I knew about the safety inspection discontinuation but I was under the impression we still had to do the emissions inspection portion, which makes no sense; Smog inspection but no safety inspection? Just doesn't make a whole lot of sense but neither do I....

"No Emissions Liberation Day"?

(January 13)

Eddie-teenth Day?

I bet they want to look for the dreaded Service Engine Soon light, though; or do OBD-I vehicles have a MIL?

"Any vehicle over 25 years old is no longer subject to emissions testing in Harris County."

FURREAL?! THIS IS INDEED GOOD NEWS!!!!!!!!!!

The "buy-the-neighbor's-truck" plot just got kicked into Warp 11!

I knew about the safety inspection discontinuation but I was under the impression we still had to do the emissions inspection portion, which makes no sense; Smog inspection but no safety inspection? Just doesn't make a whole lot of sense but neither do I....

"No Emissions Liberation Day"?

(January 13)

Eddie-teenth Day?

Last edited:

GreasyNRusty

Well-known member

Similar threads

All Small Six

Help! Did I just screw up my new build?

- Replies

- 150

- Views

- 4K

All Small Six

Ford 200

- Replies

- 9

- Views

- 1K

- Replies

- 38

- Views

- 5K

- Replies

- 8

- Views

- 958