Hey All,

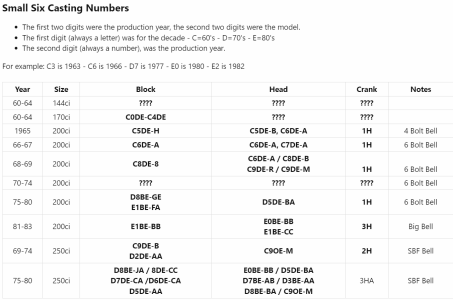

I'm new here but have spent a lot of time poking around the site. I see/hear a lot of mixed terminology for describing parts and wanted clarity. I have a couple of late 70s 200 cylinder heads; one is on my vintage Econoline and the other is on a core engine in the corner. They both have a number cast into the intake: D8BE 6090 BA. One of them has a "X" cast into it. I've discovered that these are referred to as a "large log" head, but have heard/read about octagonal, round and flat "large log" heads.

Q: which do I have and is either a good candidate for the 2V conversion? Would like to get away without brazing on the head.

I'm hoping the one with the X contains some magic!

Thanks

I'm new here but have spent a lot of time poking around the site. I see/hear a lot of mixed terminology for describing parts and wanted clarity. I have a couple of late 70s 200 cylinder heads; one is on my vintage Econoline and the other is on a core engine in the corner. They both have a number cast into the intake: D8BE 6090 BA. One of them has a "X" cast into it. I've discovered that these are referred to as a "large log" head, but have heard/read about octagonal, round and flat "large log" heads.

Q: which do I have and is either a good candidate for the 2V conversion? Would like to get away without brazing on the head.

I'm hoping the one with the X contains some magic!

Thanks