Otto

Well-known member

Before I start making carb changes, there are a couple of things that I want to iron out.

The first is the Mercarb has no provision for ported vacuum, so the distributor is connected to manifold vacuum. It’s either this or rely on the mechanical advance only. There is much debate on ported vacuum vs. manifold on the internet, so I’m curious about this. This situation only has one choice so maybe it’s a moot point.

The second and maybe more important is the PCV system. The van’s original engine had a road draft tube and that is gone. The new engine has a late model valve cover with the PCV valve in the front and the oil filler/breather in the back.The breather has a hose on the top that leads to the air cleaner. The PCV valve is connected to the intake manifold.

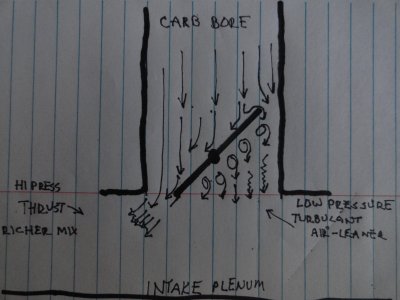

I put this together from photos on the internet.

If I pull out the PCV valve and put my thumb over it, the engine runs quite a bit smoother and obviously richer. The engine has always had a rough idle so maybe there is a fundamental flaw here. The 2V carb masks this a bit but it’s still there.

Do I have the PCV system correct?

The first is the Mercarb has no provision for ported vacuum, so the distributor is connected to manifold vacuum. It’s either this or rely on the mechanical advance only. There is much debate on ported vacuum vs. manifold on the internet, so I’m curious about this. This situation only has one choice so maybe it’s a moot point.

The second and maybe more important is the PCV system. The van’s original engine had a road draft tube and that is gone. The new engine has a late model valve cover with the PCV valve in the front and the oil filler/breather in the back.The breather has a hose on the top that leads to the air cleaner. The PCV valve is connected to the intake manifold.

I put this together from photos on the internet.

If I pull out the PCV valve and put my thumb over it, the engine runs quite a bit smoother and obviously richer. The engine has always had a rough idle so maybe there is a fundamental flaw here. The 2V carb masks this a bit but it’s still there.

Do I have the PCV system correct?