Just a side note: I like buying from independent shops when I can. The autocoolguy is a vet who builds all his units in his garage(I've been there!), so I know the $ is going to help his family. Good luck

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six New Adventures in electrics fans and inline 6’s

- Thread starter awasson

- Start date

This relates to all small sixes

Some Bronco owners looking at this option:

Liberty Electric Fan for your Early Bronco

Tech article by Viperwolf1 While gathering parts for my 5.0 EFI install I happened across a two speed electric fan from a 2004 Jeep Liberty, part number 55037669AE. This Liberty did not have the towing package. With the towing package the...

classicbroncos.com

For those who want a Chinese (made in Taiwan) fan.Some Bronco owners looking at this option:

Liberty Electric Fan for your Early Bronco

Tech article by Viperwolf1 While gathering parts for my 5.0 EFI install I happened across a two speed electric fan from a 2004 Jeep Liberty, part number 55037669AE. This Liberty did not have the towing package. With the towing package the...classicbroncos.com

I had such an awesome time tinkering with the Mustang this weekend. It’s running so well and is just at home on the highway at 60 - 70 MPH in 5th. It’s just such a capable and fun car now that’s well sorted.

One thing I did this weekend was mess about with the electric fan. The fan I have is just under 3” deep at the motor and it’s too deep to go on the engine side, unless I move the rad farther forwards towards the grill about an inch AND it’s too deep to go on the grill side without moving the rad farther back, towards the engine by about a half inch. Well, one thing lead to another and before you know it, I had the grill off and the hood release mechanism off and I’m moving the radiator back towards the engine a half inch.

I haven’t wired in he temp sensor yet and I’m adding a manual override toggle under the dash so if I need a little extra cooling, I can add it on demand. I mounted the radiator on rubber bushings I had left over from the shocks I replaced a while back. They were the perfect size.

One thing I did this weekend was mess about with the electric fan. The fan I have is just under 3” deep at the motor and it’s too deep to go on the engine side, unless I move the rad farther forwards towards the grill about an inch AND it’s too deep to go on the grill side without moving the rad farther back, towards the engine by about a half inch. Well, one thing lead to another and before you know it, I had the grill off and the hood release mechanism off and I’m moving the radiator back towards the engine a half inch.

I haven’t wired in he temp sensor yet and I’m adding a manual override toggle under the dash so if I need a little extra cooling, I can add it on demand. I mounted the radiator on rubber bushings I had left over from the shocks I replaced a while back. They were the perfect size.

Nice! It's said a pusher is more efficient than a puller. . . One thing, with the gap now present between the rad and support, there is reduced effective airflow thru the rad area not under the fan shroud. . The gap affects airflow patterns under the hood too. (Not that most folks give that much thought, but we're not most folks). . I know this from moving the rad back in a truck, cooling efficiency went down and partially offset the effectiveness of the electric fan. Sealing the perimeter restored cooling efficiency. (My el. fan covers a smaller radiator area than yours.)

Perhaps your next weekend project: seal the gap around the radiator.

Perhaps your next weekend project: seal the gap around the radiator.

if you can just move radiator without collateral issues it sounds simplest.

/

... the '74 Maverick , the radiator needed to be moved forward to clear SC drives. The stamped steel Grill / hood latch support is cut down and angle iron welded to re-enforce. The late Mustang radiator has sides filled but notice OEM battery area venting.

.

.

.  .

.  .

.

.

I had installed a big puller elec fan but oddly the good old WP fan seems better handling temps under boost, maybe the slower reaction of sensor vs constant WP fan when engine is at boost RPM's (?).

.

have fun

.

/

... the '74 Maverick , the radiator needed to be moved forward to clear SC drives. The stamped steel Grill / hood latch support is cut down and angle iron welded to re-enforce. The late Mustang radiator has sides filled but notice OEM battery area venting.

.

.

.  .

.  .

.

.

I had installed a big puller elec fan but oddly the good old WP fan seems better handling temps under boost, maybe the slower reaction of sensor vs constant WP fan when engine is at boost RPM's (?).

.

have fun

.

Nice! It's said a pusher is more efficient than a puller. . . One thing, with the gap now present between the rad and support, there is reduced effective airflow thru the rad area not under the fan shroud. . The gap affects airflow patterns under the hood too. (Not that most folks give that much thought, but we're not most folks). . I know this from moving the rad back in a truck, cooling efficiency went down and partially offset the effectiveness of the electric fan. Sealing the perimeter restored cooling efficiency. (My el. fan covers a smaller radiator area than yours.)

Perhaps your next weekend project: seal the gap around the radiator.

Yes, I think I'll have to come up with a gasket to fill in the gap. I've still got to make my tin heat deflector for the header too.

Just for edification:- This is a 400mm Australian made fan, it draws 16A running and 30A starting, I have a 130A alternator which is able to cover this at idle. the fan is cable tied to the radiator tubes. this works in Australia climate on the east coast, i have a blown 3.3 litre six with a two row v8 rad. I manually control it via a relay.

Just for edification:- This is a 400mm Australian made fan, it draws 16A running and 30A starting, I have a 130A alternator which is able to cover this at idle. the fan is cable tied to the radiator tubes. this works in Australia climate on the east coast, i have a blown 3.3 litre six with a two row v8 rad. I manually control it via a relay.View attachment 27573

That is very similar to the one I put in. Mine is 400mm and draws about 13amps when it’s running. I’m not sure what the startup current is but my charging system doesn’t seem to mind even with the halogen headlamps on, at idle. It’s rated for 2600 CFM which is plenty. I have run it on a hot day and it cooled the radiator better than the stock fan. I’ve got it wired to a relay with a manual toggle under the dash. I’ll put in the temperature sensor once I get the hose coupler. That should be here later this week.

Black Starboard looks very similar to the plastic on the fans, easy to work with, heat it with a heat gun and you can bend it.Yes, I think I'll have to come up with a gasket to fill in the gap. I've still got to make my tin heat deflector for the header too.

Taiwanese products are 100% better quality than Chinese. Why do you think the USA wants to stop China from invading Taiwan? Taiwan make so many items for the likes of Ford USA and Australia. Think computer chips. A couple of US publications (magazines) recently visited Taiwan to see reproduction parts and how they are made. Have a look at this on You Tube >For those who want a Chinese (made in Taiwan) fan.

using a 3G (‘94+) alternator

“...mentioned the Windstar (’95/03) alternator as an upgrade and a modern charging system. Is the Windstar alt a 90 amp unit? I recall a Taurus 90 amp alt as having been used somewhat often. I am interested because I want to upgrade my alt which I believe may be a 60 amp provided on 1966 Broncos stock. I am planning on several additions to my Bronco like electric cooling fan, halogen headlights on relay and 5 channel speaker amp as definite additions and then possible electric fuel pump and a somewhat remote possibility of heat seating elements. So after reviewing my list of definite additions I am hoping 90 amp will be enough for me. If I add everything on my list then I would probably need an even larger alt..."

some put in the “1 wire” (means GM of same vintage) the ford has some advantages. ‘3' “G” just means 3rd generation I suppose. One reason I got it was to smooth the engine bay (has internal regulator). Nother is 150 -225 amps (depending on which one) & I gota bronk ("lights camera action” ofa utility vehicle). I paid 80$ i think (DB Ele) & back fitted a 1 groove shive (the serp style takes more tq but I have all v-belts). Needed a different ele clip, put in mini starter too so hada go bigger cable + a mega fuse. Last, will need to swap from volt gauge on dash to amp. Hopin my wiring is ok (55 yrs old). Wish I had the automotive theory/wiring knowledge somea U guy have. ’S my worse topic (esp since I missed all automotive changes from early 80’s to now - efi, most ‘sensors’, OBD, computers, ele fuel pump, etc). Tryin to catch up 45 yrs now as I futz around in 3 bay 4 lift garage...

“...mentioned the Windstar (’95/03) alternator as an upgrade and a modern charging system. Is the Windstar alt a 90 amp unit? I recall a Taurus 90 amp alt as having been used somewhat often. I am interested because I want to upgrade my alt which I believe may be a 60 amp provided on 1966 Broncos stock. I am planning on several additions to my Bronco like electric cooling fan, halogen headlights on relay and 5 channel speaker amp as definite additions and then possible electric fuel pump and a somewhat remote possibility of heat seating elements. So after reviewing my list of definite additions I am hoping 90 amp will be enough for me. If I add everything on my list then I would probably need an even larger alt..."

some put in the “1 wire” (means GM of same vintage) the ford has some advantages. ‘3' “G” just means 3rd generation I suppose. One reason I got it was to smooth the engine bay (has internal regulator). Nother is 150 -225 amps (depending on which one) & I gota bronk ("lights camera action” ofa utility vehicle). I paid 80$ i think (DB Ele) & back fitted a 1 groove shive (the serp style takes more tq but I have all v-belts). Needed a different ele clip, put in mini starter too so hada go bigger cable + a mega fuse. Last, will need to swap from volt gauge on dash to amp. Hopin my wiring is ok (55 yrs old). Wish I had the automotive theory/wiring knowledge somea U guy have. ’S my worse topic (esp since I missed all automotive changes from early 80’s to now - efi, most ‘sensors’, OBD, computers, ele fuel pump, etc). Tryin to catch up 45 yrs now as I futz around in 3 bay 4 lift garage...

Awhile back I did a bit of research into donor vehicles for 3G alts (scrounging around picnpull is fun for me) and several 90's models like taurus and aerostar were equipped with 90 and 95 amp 3G alts although those might be getting scarse in the yards. The main advantage of the 3G is it provides more amps at lower rpms.using a 3G (‘94+) alternator

“...mentioned the Windstar (’95/03) alternator as an upgrade and a modern charging system. Is the Windstar alt a 90 amp unit? I recall a Taurus 90 amp alt as having been used somewhat often. I am interested because I want to upgrade my alt which I believe may be a 60 amp provided on 1966 Broncos stock. I am planning on several additions to my Bronco like electric cooling fan, halogen headlights on relay and 5 channel speaker amp as definite additions and then possible electric fuel pump and a somewhat remote possibility of heat seating elements. So after reviewing my list of definite additions I am hoping 90 amp will be enough for me. If I add everything on my list then I would probably need an even larger alt..."

some put in the “1 wire” (means GM of same vintage) the ford has some advantages. ‘3' “G” just means 3rd generation I suppose. One reason I got it was to smooth the engine bay (has internal regulator). Nother is 150 -225 amps (depending on which one) & I gota bronk ("lights camera action” ofa utility vehicle). I paid 80$ i think (DB Ele) & back fitted a 1 groove shive (the serp style takes more tq but I have all v-belts). Needed a different ele clip, put in mini starter too so hada go bigger cable + a mega fuse. Last, will need to swap from volt gauge on dash to amp. Hopin my wiring is ok (55 yrs old). Wish I had the automotive theory/wiring knowledge somea U guy have. ’S my worse topic (esp since I missed all automotive changes from early 80’s to now - efi, most ‘sensors’, OBD, computers, ele fuel pump, etc). Tryin to catch up 45 yrs now as I futz around in 3 bay 4 lift garage...

As far as wiring goes many on this forum have upgraded to 90 amp and more so I plan to make all the big cables bigger and use relays for radiator fan, halogen headlights, heater blower motor etc.

My dash currently has an ammeter but will get this voltmeter:

High Quality, Very Accurate, Direct Fit Voltmeters Now Available!!

We are very excited to release our new direct fit voltmeter. We have spent alot of time getting the face and needle as accurate as possible. These are a super easy install and look completely factory! Very high quality, accurate gauge at a super affordable price! Check them out at...

classicbroncos.com

Voltmeter / Voltage Gauge. 8-18V. New. 66-77 Bronco 61 66 truck

Voltmeter / Voltage Gauge. 8-18V. New. 1966 1967 1968 1969 1970 1971 1972 1973 1974 1975 1976 1977 early ford bronco

chad, perhaps the '66 bronk was different, stock alternators of that era were lucky to have 45 amps. The generators these replaced were 25 amp.using a 3G (‘94+) alternator

“...mentioned the Windstar (’95/03) alternator as an upgrade and a modern charging system. Is the Windstar alt a 90 amp unit? I recall a Taurus 90 amp alt as having been used somewhat often. I am interested because I want to upgrade my alt which I believe may be a 60 amp provided on 1966 Broncos stock. I am planning on several additions to my Bronco like electric cooling fan, halogen headlights on relay and 5 channel speaker amp as definite additions and then possible electric fuel pump and a somewhat remote possibility of heat seating elements. So after reviewing my list of definite additions I am hoping 90 amp will be enough for me. If I add everything on my list then I would probably need an even larger alt..."

some put in the “1 wire” (means GM of same vintage) the ford has some advantages. ‘3' “G” just means 3rd generation I suppose. One reason I got it was to smooth the engine bay (has internal regulator). Nother is 150 -225 amps (depending on which one) & I gota bronk ("lights camera action” ofa utility vehicle). I paid 80$ i think (DB Ele) & back fitted a 1 groove shive (the serp style takes more tq but I have all v-belts). Needed a different ele clip, put in mini starter too so hada go bigger cable + a mega fuse. Last, will need to swap from volt gauge on dash to amp. Hopin my wiring is ok (55 yrs old). Wish I had the automotive theory/wiring knowledge somea U guy have. ’S my worse topic (esp since I missed all automotive changes from early 80’s to now - efi, most ‘sensors’, OBD, computers, ele fuel pump, etc). Tryin to catch up 45 yrs now as I futz around in 3 bay 4 lift garage...

Yes that is correct. I never confirmed I had a 60 amp alt just guessed at it most likely or possibly upgraded the amp somewhere along the line as I have owned my 66 since the mid 80s and I forget a lot of things.chad, perhaps the '66 bronk was different, stock alternators of that era were lucky to have 45 amps. The generators these replaced were 25 amp.

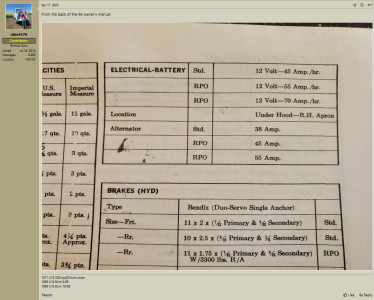

Found this:

Well, I removed the 6 blade belt driven fan from my car and am just using the pusher fan. It’s a lot quieter without the mechanical fan. Like a lot. It’s smoother too. It’s noticeably smoother when it’s cold and warming up. I think my stock 6 blade fan is poorly balanced and that come through when the engine is cold. That’s just a hunch. I haven’t checked the balance out.

I was out for about an hour driving around with mostly the electric fan off. I was just driving around town in fairly decent traffic. Heavy enough but not stop and go, rush hour traffic. Lots of traffic lights and slow traffic but it performed great. It’s mid October and that means the air is pretty cool and dense. It would be better with a fresh cold air intake, through the firewall but it was pretty ok without and the phenolic spacer between the carb and intake keeps the carb from getting hot. It’s cool to the touch. Not cold, just not warm.

At about 45 minutes in, I was stuck behind half a dozen cars at a stop sign controlled entrance to a busy street and the temp climbed up to about 3/4 on the temp gauge so I switched it on with my manual override switch. It cooled down pretty quick and there were no issues.

My temp sensor (Amazon) doesn’t seem to be working. It’s a 1/8” NPT 200 degree switch and it is supposed to switch closed at 200 degrees and turn off at 185 degrees. I’ve got the housing grounded and the other side goes to the relay coil with +12v on the other side. I’ve checked and the sensor housing is seeing ground. The issue is that the sensor shows me about 85 ohms to ground when it’s just sitting and when it’s getting hot coolant, it’s open. I’ll reach out to the vendor to get a replacement. Fortunately, I wired in an override toggle under the dash that switches ground to the relay so I can switch it on as needed.

Anyway, that’s where we are currently. I’ll be adding my cold air intake next. Then I think it’ll be perfect. Cowl induction would be ideal but I don’t feel like buying a new hood.

I was out for about an hour driving around with mostly the electric fan off. I was just driving around town in fairly decent traffic. Heavy enough but not stop and go, rush hour traffic. Lots of traffic lights and slow traffic but it performed great. It’s mid October and that means the air is pretty cool and dense. It would be better with a fresh cold air intake, through the firewall but it was pretty ok without and the phenolic spacer between the carb and intake keeps the carb from getting hot. It’s cool to the touch. Not cold, just not warm.

At about 45 minutes in, I was stuck behind half a dozen cars at a stop sign controlled entrance to a busy street and the temp climbed up to about 3/4 on the temp gauge so I switched it on with my manual override switch. It cooled down pretty quick and there were no issues.

My temp sensor (Amazon) doesn’t seem to be working. It’s a 1/8” NPT 200 degree switch and it is supposed to switch closed at 200 degrees and turn off at 185 degrees. I’ve got the housing grounded and the other side goes to the relay coil with +12v on the other side. I’ve checked and the sensor housing is seeing ground. The issue is that the sensor shows me about 85 ohms to ground when it’s just sitting and when it’s getting hot coolant, it’s open. I’ll reach out to the vendor to get a replacement. Fortunately, I wired in an override toggle under the dash that switches ground to the relay so I can switch it on as needed.

Anyway, that’s where we are currently. I’ll be adding my cold air intake next. Then I think it’ll be perfect. Cowl induction would be ideal but I don’t feel like buying a new hood.

I'm having a hard time finding a good 1/8" NPT (200 Degree on 185 Degree Off) rad hose temperature switch. The one I installed earlier this week didn't work. The relay for the fan triggers if the sensor output is grounded to its case so my circuit it does indeed work but the sensor was defective so I ordered another. The new one is the same. Does anyone know a good source for a decent thermal switch? The only requirement is that it's a 1/8" NPT because the sleeve I'm using on the radiator top hose is pretty small.

Fortunately I can toggle the override switch under the dash and as long as the engine is running, so is the fan. It keeps it cooler than the mechanical one did too. If it's running full time (cooler weather because of the fall), my temp gauge sits at between 1/3 and 1/2.

The little sensor that doesn't work, looks like this

On my car, it looks like this

Fortunately I can toggle the override switch under the dash and as long as the engine is running, so is the fan. It keeps it cooler than the mechanical one did too. If it's running full time (cooler weather because of the fall), my temp gauge sits at between 1/3 and 1/2.

The little sensor that doesn't work, looks like this

On my car, it looks like this

Similar threads

- Replies

- 6

- Views

- 518

- Replies

- 16

- Views

- 879

All Small Six

Thinking of Ideas for 200 upgrades

- Replies

- 21

- Views

- 634

- Replies

- 17

- Views

- 2K

- Replies

- 5

- Views

- 1K