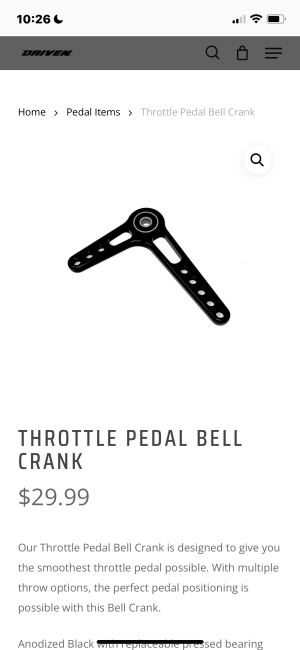

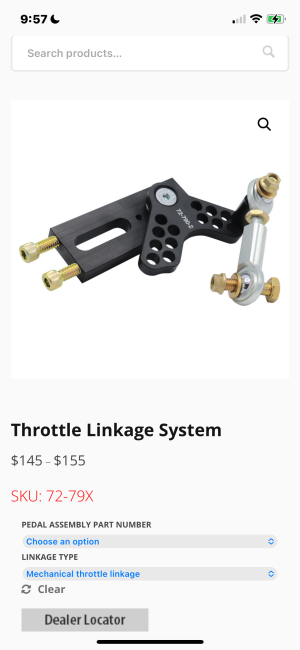

I have the linkage in picture #1. I don't see how I can get it to work in general but I think with an adjustable linkage i could use the plate circled in picture #2 since the rod just needs to push up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Weber 32/36 rough idle

- Thread starter beanmiester

- Start date

This relates to all small sixes

I have the linkage in picture #1. I don't see how I can get it to work in general but I think with an adjustable linkage i could use the plate circled in picture #2 since the rod just needs to push up

Here's a discussion I found that uses parts similar to yours to orient the carb with the bowl in the front and the linkage in the back: https://www.vintage-mustang.com/threads/correct-carb-for-1966-6-cyl-mustang.1160010/

This is a pretty good photo showing the linkage mechanism. His carb is different and uses a manual choke cable but it's similar enough to get the idea of what he's done.

It looks like he took that square ish bracket that came on the carb and bent it to make it work?

Ok so i would like some input. Ive been thinking about getting into cnc machining and making an adapter would be a good enough reason to get into it. I already have experience with fusion 360 so id just have to refresh myself with that. I was wondering if there would be any sort of need for an adapter that orientated a weber the factory preferred way? I know I need it but if others want one then id put in effort designing a nice looking and working adapter instead of a block with a notch cut out so it doesn't hit the valve cover

Ive been thinking that im tired of having issue after issue with parts so why not make a few of the simple ones. Plus I could also cut gaskets. I know its not hard to cut gaskets by hand (even though i failed cutting in kindergarten)but then id have perfectly machined gaskets.

Ive been thinking that im tired of having issue after issue with parts so why not make a few of the simple ones. Plus I could also cut gaskets. I know its not hard to cut gaskets by hand (even though i failed cutting in kindergarten)but then id have perfectly machined gaskets.

Interestingly enough, I finally experienced the downside of the sideways mount weber the other day when I was pushing mine through an uphill sweeping right hand corner. I was pushing it a little bit so it definitely had some G-force on the fuel in the bowl and my thoughts went exactly to this discussion and what @63 Sprint mentioned earlier about that issue.

As @DON mentioned, if you could come up with an adapter that mounts it correctly and come up with the mechanical linkage to connect to the existing throttle lever, it would be ideal. I'd want one for sure.

Also, make sure you install the phenolic spacer on yours when you get it. I installed mine on Tuesday and wow... Big improvement on the way mine runs and I was pretty happy to begin with.

As @DON mentioned, if you could come up with an adapter that mounts it correctly and come up with the mechanical linkage to connect to the existing throttle lever, it would be ideal. I'd want one for sure.

Also, make sure you install the phenolic spacer on yours when you get it. I installed mine on Tuesday and wow... Big improvement on the way mine runs and I was pretty happy to begin with.

Lol. Well at least it happened after we discussed it so now you know why it did that. I am waiting for the spacer.

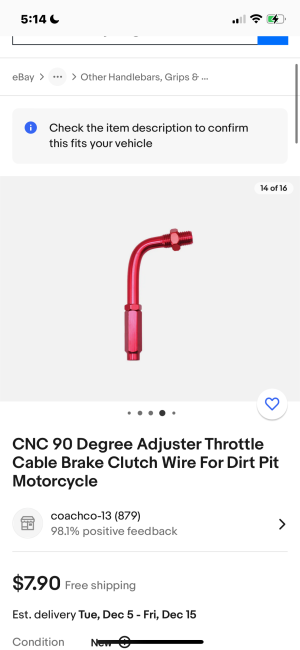

Right now im thinking of a way to keep the stock linkage/long adjustable linkage. Something like what is in that picture you sent would work. I just cant figure out what lever the guy is using. I think the universal plate you see for using a cable might work. Ill have to see when I install the carb. Im thinking it might put the linkage too close to the engine or it might have a hard time going full throttle

I also made the Facebook i6 people mad by talking about the "correct" way to mount the weber I even quoted it like I just did to signify its not the only way to mount it. Its just the technically right way to mount it

Im just trying to find linkage ideas lol

Right now im thinking of a way to keep the stock linkage/long adjustable linkage. Something like what is in that picture you sent would work. I just cant figure out what lever the guy is using. I think the universal plate you see for using a cable might work. Ill have to see when I install the carb. Im thinking it might put the linkage too close to the engine or it might have a hard time going full throttle

I also made the Facebook i6 people mad by talking about the "correct" way to mount the weber I even quoted it like I just did to signify its not the only way to mount it. Its just the technically right way to mount it

Im just trying to find linkage ideas lol

Also this all hinges on if I decide to get a cnc machine. Im trying to convince my dad by offering to make parts for his fish tank hobby

This is if you were to make an adapter that mounts the carb the correct way, not the sideways way I’ve got it on mine.

I think it will involve making a small platform that hard mounts to the log (an exhaust stud maybe?) and maybe a carb stud, so that it is solid and can support a rotating cog that is oriented at 90 degrees to the throttle shaft so that it is aligned with the carburetor throttle shaft. Then a rod can be connected along the top of this cog to the cog on the Weber throttle shaft so if you rotate the cog on the platform, counter clockwise, it rotates the throttle shaft counter clockwise to accelerate. You could put a throttle return spring on the base too and make it a tidy package.

The accelerator pedal rod would be beside this platform and would probably need to be bent up like they recommend from the Clifford/redline instructions so that a rod with ball joints on both ends could be attached to the accelerator pedal shaft to the rotating cog. Press on the accelerator and the rod pulls up on the cog and rotates it counter clockwise.

I think that would work but, you’d want to experiment with different diameters for the rotating cog to make sure that you could get the most movement on throttle pedal to open close the Weber. I think the rotating cog would have a larger diameter than the one that’s on the carb so you could get the right amount of travel.

I think it will involve making a small platform that hard mounts to the log (an exhaust stud maybe?) and maybe a carb stud, so that it is solid and can support a rotating cog that is oriented at 90 degrees to the throttle shaft so that it is aligned with the carburetor throttle shaft. Then a rod can be connected along the top of this cog to the cog on the Weber throttle shaft so if you rotate the cog on the platform, counter clockwise, it rotates the throttle shaft counter clockwise to accelerate. You could put a throttle return spring on the base too and make it a tidy package.

The accelerator pedal rod would be beside this platform and would probably need to be bent up like they recommend from the Clifford/redline instructions so that a rod with ball joints on both ends could be attached to the accelerator pedal shaft to the rotating cog. Press on the accelerator and the rod pulls up on the cog and rotates it counter clockwise.

I think that would work but, you’d want to experiment with different diameters for the rotating cog to make sure that you could get the most movement on throttle pedal to open close the Weber. I think the rotating cog would have a larger diameter than the one that’s on the carb so you could get the right amount of travel.

All I got from that was cog  . It does sound like it would work though. I am trying to figure out a way that wouldn't require modification so anyone could easily do it. Im thinking a 2-3 inch ish lever that would attach to the carburetor to keep the pedal and linkage in line with how it would be stock. The lever could be bent to whatever angle workes best for each individual circumstance. Like what that one guy had. I think it should work based on how the jeep linkage i used had a way more aggressive angle it was trying to push the throttle lever up. I have seen a cog design used but it was with a cable setup.

. It does sound like it would work though. I am trying to figure out a way that wouldn't require modification so anyone could easily do it. Im thinking a 2-3 inch ish lever that would attach to the carburetor to keep the pedal and linkage in line with how it would be stock. The lever could be bent to whatever angle workes best for each individual circumstance. Like what that one guy had. I think it should work based on how the jeep linkage i used had a way more aggressive angle it was trying to push the throttle lever up. I have seen a cog design used but it was with a cable setup.

There's a ton of ways. Im thinking ill prototype a few at some point and maybe we can get people to vote on which one they like the best.

Also if we can get it to work like how it would for an autolite then the return spring won't have to be customized. With my current setup it was stretching my spring

There's a ton of ways. Im thinking ill prototype a few at some point and maybe we can get people to vote on which one they like the best.

Also if we can get it to work like how it would for an autolite then the return spring won't have to be customized. With my current setup it was stretching my spring

Update. My engineering teacher liked the idea so I don't have to get my own cnc machine just yet. I will get the 3d file from him though and share it with you all when a working adapter is made. Im thinking two versions. One for mounting directly to the manifold and one for mounting with a spacer like my adapter is on.

So if anyone has any wants that are easy to figure out without them having the actual car let me know. He's going to have his students model it as an assignment if i give him the information

So if anyone has any wants that are easy to figure out without them having the actual car let me know. He's going to have his students model it as an assignment if i give him the information

I have the modified two barrel intake. If the adapter was made to fit the two barrel on top and bottom, it would fit both adapters and modified 2 barrel intakesUpdate. My engineering teacher liked the idea so I don't have to get my own cnc machine just yet. I will get the 3d file from him though and share it with you all when a working adapter is made. Im thinking two versions. One for mounting directly to the manifold and one for mounting with a spacer like my adapter is on.

So if anyone has any wants that are easy to figure out without them having the actual car let me know. He's going to have his students model it as an assignment if i give him the information

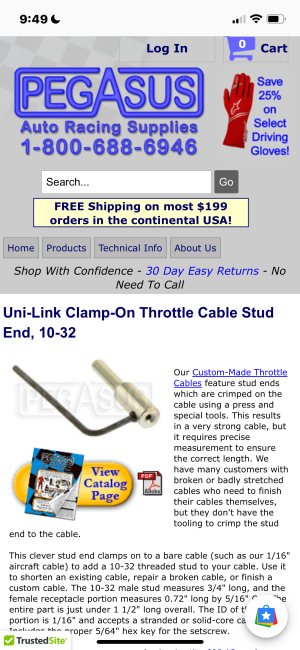

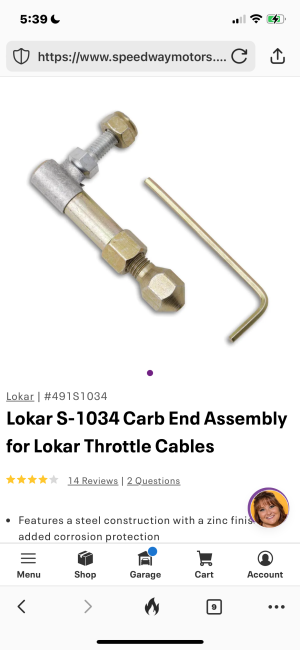

I can up with a simple, effective, return spring setup that will work with a variety of springs. On my 67 mustang, a rod is used to go from the throttle lever linkage on the firewall to the carb, I used a stainless threaded rod, the threaded connectors at the ends( gimble type- not sure if proper name). Then for the return spring, I used a nut with a square tab welded to it, drilled a hole in the tab, thread it and a lock nut onto the rod ( before the gimble end is installed ) and run it up the threads to what ever length you need for the spring to have the desired tension, the lock it in place with the lock nut. The other end of the spring ( on mine) is attached to a simple L bracket ( chrome of course!!) mounted on a carb stud. I can send a photo if you don’t follow

Photos please. They always help  .

.

I could see if they would be willing to make a design for the modified intake. If not I could always modify their design

I could see if they would be willing to make a design for the modified intake. If not I could always modify their design

Similar threads

- Replies

- 29

- Views

- 4K

- Replies

- 7

- Views

- 3K

- Replies

- 5

- Views

- 3K

- Replies

- 19

- Views

- 5K

- Replies

- 38

- Views

- 8K