Hello all, I installed a reground original 60s cam earlier this year in my ‘65 200. I did not degree it. It is a mild performance grind. I was told bolt it in and go. It is a new rebuilt engine and doesn’t idle well, doesn’t accelerate well, has weak, unstable vacuum at idle and won’t rev over 3800. I have been chasing carb and ignition as the cause but maybe it’s the cam. Where can I find a cam degree kit for a 200? Thank you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

200ci Degree the cam?

- Thread starter Dustyford

- Start date

This applies only to 200ci

Who reground the cam. I had Schneider regrind a 200 cam for me and it was so far off that I threw it away and bought a Clay cam. I was very happy with clay cams and they had many in stock to chose from. I had them send me all the cam grinds in stock and I picked one.

Yes you must degree the cam. To many horror stories and personal experience.

Yes you must degree the cam. To many horror stories and personal experience.

Hi, in the search box, look up Echo 1955 videos. I checked the link and it works. Echo 1955 documented his engine rebuild in a fun and educational way. You will see the piston stop, degree wheel, and dial indicator in action. Echo 1955 shows how to measure the cam events and do the math. Bubba made sure the videos were preserved. Unfortunately, we have lost both of these members. Good luck.

Thank you. And thanks to those who gave so much.Hi, in the search box, look up Echo 1955 videos. I checked the link and it works. Echo 1955 documented his engine rebuild in a fun and educational way. You will see the piston stop, degree wheel, and dial indicator in action. Echo 1955 shows how to measure the cam events and do the math. Bubba made sure the videos were preserved. Unfortunately, we have lost both of these members. Good luck.

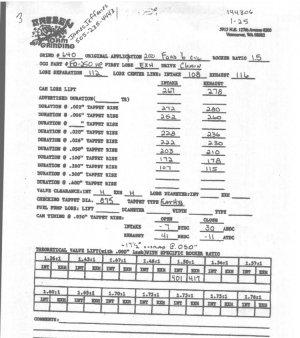

It was Oregon Cams. I am posting a photo of cam card.Who reground the cam. I had Schneider regrind a 200 cam for me and it was so far off that I threw it away and bought a Clay cam. I was very happy with clay cams and they had many in stock to chose from. I had them send me all the cam grinds in stock and I picked one.

Yes you must degree the cam. To many horror stories and personal experience.

You only need to check for a big timing error at the camshaft that would cause your engine to run badly.

Looking at the cam card, the #1 cylinder intake pushrod would lift .050" at 7 degrees ATDC.

See "Cam Timing @ .050" Tappet Rise:" where it shows Intake Open -7 BTDC

-7 BTDC translates to 7 ATDC

If you want to double check using the cam specs shown in the upper half of the card.

Cam timing Lobe center line is 108 ATDC

Intake duration @ .050" is 203.

From the center of the intake lobe to the .050" lift point = 203/2 = 101.5 degrees

108 - 101.5 = 6.5 degrees ATDC.

Round up to 7 degrees ATDC.

Remove the valve cover.

Then turn the crankshaft clockwise until the #1 intake pushrod is all the way down and the #1 intake valve is closed.

Then put a dial indicator on the #1 intake rocker arm just over the pushrod and zero the dial.

Then turn the crankshaft clockwise slowly until the pushrod end of the rocker arm rises .050" and stop.

Look at the timing mark on the harmonic balancer and it should be close to 7 degrees ATDC.

Looking at the cam card, the #1 cylinder intake pushrod would lift .050" at 7 degrees ATDC.

See "Cam Timing @ .050" Tappet Rise:" where it shows Intake Open -7 BTDC

-7 BTDC translates to 7 ATDC

If you want to double check using the cam specs shown in the upper half of the card.

Cam timing Lobe center line is 108 ATDC

Intake duration @ .050" is 203.

From the center of the intake lobe to the .050" lift point = 203/2 = 101.5 degrees

108 - 101.5 = 6.5 degrees ATDC.

Round up to 7 degrees ATDC.

Remove the valve cover.

Then turn the crankshaft clockwise until the #1 intake pushrod is all the way down and the #1 intake valve is closed.

Then put a dial indicator on the #1 intake rocker arm just over the pushrod and zero the dial.

Then turn the crankshaft clockwise slowly until the pushrod end of the rocker arm rises .050" and stop.

Look at the timing mark on the harmonic balancer and it should be close to 7 degrees ATDC.

Last edited:

Thanks. I will have to borrow a dial indicator and get back to you.You only need to check for a big timing error at the camshaft that would cause your engine to run badly.

Looking at the cam card, the #1 cylinder intake pushrod would lift .050" at 7 degrees ATDC.

See "Cam Timing @ .050" Tappet Rise:" where it shows Intake Open -7 BTDC

-7 BTDC translates to 7 ATDC

If you want to double check using the cam specs shown in the upper half of the card.

Cam timing Lobe center line is 108 ATDC

Intake duration @ .050" is 203.

From the center of the intake lobe to the .050" lift point = 203/2 = 101.5 degrees

108 - 101.5 = 6.5 degrees ATDC.

Round up to 7 degrees ATDC.

Remove the valve cover.

Then turn the crankshaft clockwise until the #1 intake pushrod is all the way down and the #1 intake valve is closed.

Then put a dial indicator on the #1 intake rocker arm just over the pushrod and zero the dial.

Then turn the crankshaft clockwise slowly until the pushrod end of the rocker arm rises .050" and stop.

Look at the timing mark on the harmonic balancer and it should be close to 7 degrees ATDC.

Here is picture of the line at .050 open. It seems quite a bit more than 7* ATDC. White mark at top is 10* BTDCYou only need to check for a big timing error at the camshaft that would cause your engine to run badly.

Looking at the cam card, the #1 cylinder intake pushrod would lift .050" at 7 degrees ATDC.

See "Cam Timing @ .050" Tappet Rise:" where it shows Intake Open -7 BTDC

-7 BTDC translates to 7 ATDC

If you want to double check using the cam specs shown in the upper half of the card.

Cam timing Lobe center line is 108 ATDC

Intake duration @ .050" is 203.

From the center of the intake lobe to the .050" lift point = 203/2 = 101.5 degrees

108 - 101.5 = 6.5 degrees ATDC.

Round up to 7 degrees ATDC.

Remove the valve cover.

Then turn the crankshaft clockwise until the #1 intake pushrod is all the way down and the #1 intake valve is closed.

Then put a dial indicator on the #1 intake rocker arm just over the pushrod and zero the dial.

Then turn the crankshaft clockwise slowly until the pushrod end of the rocker arm rises .050" and stop.

Look at the timing mark on the harmonic balancer and it should be close to 7 degrees ATDC.

The cam card asks for the intake lobe center to be at 108 which is 4 degrees advanced when the .050" point is at 7 degrees ATDC.Here is picture of the line at .050 open. It seems quite a bit more than 7* ATDC. White mark at top is 10* BTDC

The intake lobe center appears to be retarded from 7 ATDC position but even if it is at say 15 degrees ATDC that would put the cam 4 degrees retarded instead of 4 degrees advanced which would not make the engine run poorly.

It would simply shift the power band higher.

The stock 300 six cam is run at 4 degrees retarded.

You can check the timing again with the #1 intake valve adjustment loose so that the valve spring is not pushing down on the lifter plunger at .050" lifter lift.

After this exercise, I would do a compression check on all the cylinders just to be sure the engine is fine mechanically and all the valves are closing.

Last edited:

Thanks P. I have 150-160 psi compression. So I shouldn’t have to degree my cam then? Any idea why rpms are limited?The cam card asks for the intake lobe center to be at 108 which is 4 degrees advanced when the .050" point is at 7 degrees ATDC.

The intake lobe center appears to be retarded from 7 ATDC position but even if it is at say 15 degrees ATDC that would put the cam 4 degrees retarded instead of 4 degrees advanced which would not make the engine run poorly.

It would simply shift the power band higher.

The stock 300 six cam is run at 4 degrees retarded.

You can check the timing again with the #1 intake valve adjustment loose so that the valve spring is not pushing down on the lifter plunger at .050" lifter lift.

After this exercise, I would do a compression check on all the cylinders just to be sure the engine is fine mechanically and all the valves are closing at the correct valve timing.

If all the cylinders have between 150 and 160 psi, your cam timing is ok, the valve train is OK and the engine is fine mechanically.Thanks P. I have 150-160 psi compression. So I shouldn’t have to degree my cam then? Any idea why rpms are limited?

Next question is: What does the ignition timing look like using a timing light?

I have been playing with the carb for months. I try to keep the timing at 10* BTDC as you can see the white mark on the timing scale on the timing chain cover. Whether I’m running my idle at 520 or 750 trying to get it to run better I always start with 10*. It’s never a steady 10*, moving from 9.8-10.2 or so.If all the cylinders have between 150 and 160 psi, your cam timing is ok, the valve train is OK and the engine is fine mechanically.

Next question is: What does the ignition timing look like using a timing light?

Yes. Just to give you more info ahead of time, the engine has 200 miles on it. I have a ‘68 non SCV carb and a new replacement ‘68 dual advance distributor that was recurved to my specs by Dan Nolan.Does the timing advance with rpm?

Similar threads

- Replies

- 9

- Views

- 978

All Small Six

Starting new build

- Replies

- 114

- Views

- 8K

All Small Six

Keeping the carb cool

- Replies

- 61

- Views

- 4K

- Replies

- 20

- Views

- 1K

All Small Six

Chasing vacuum leaks..the saga has ended.

- Replies

- 41

- Views

- 4K