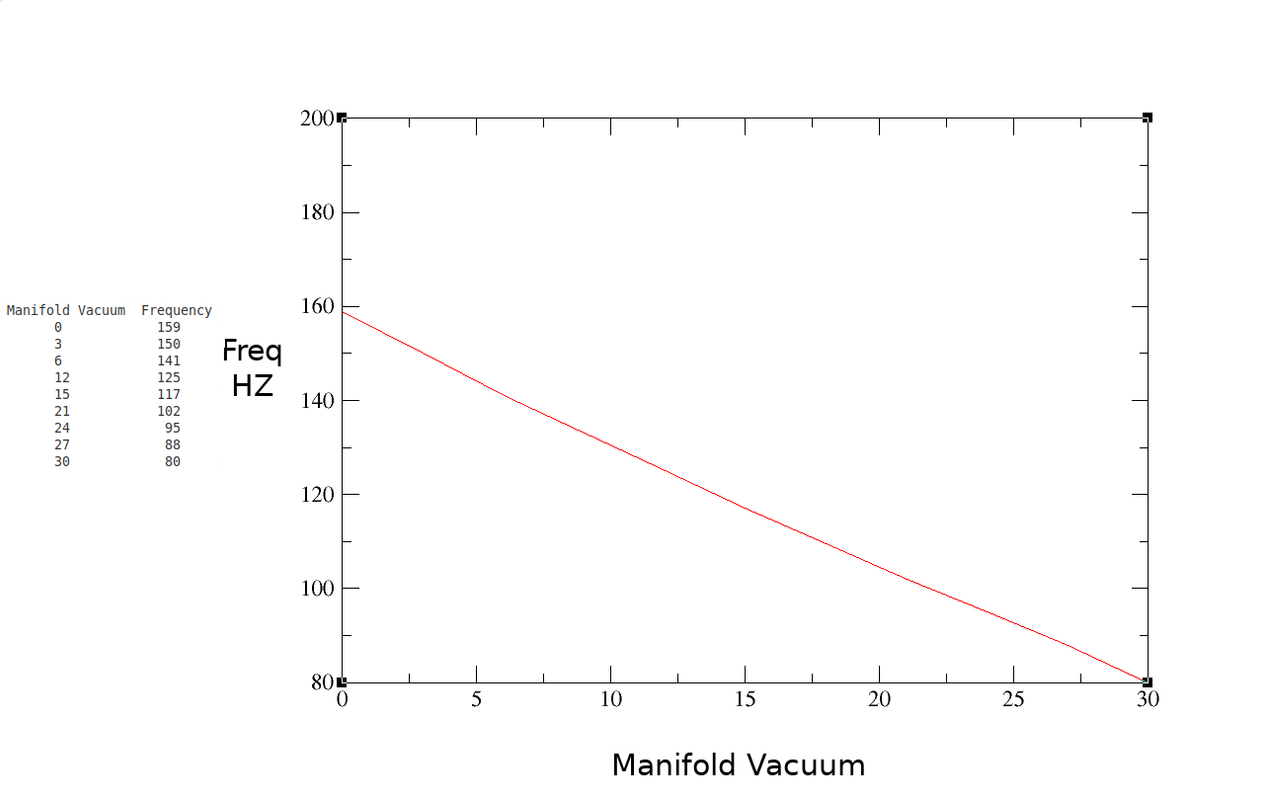

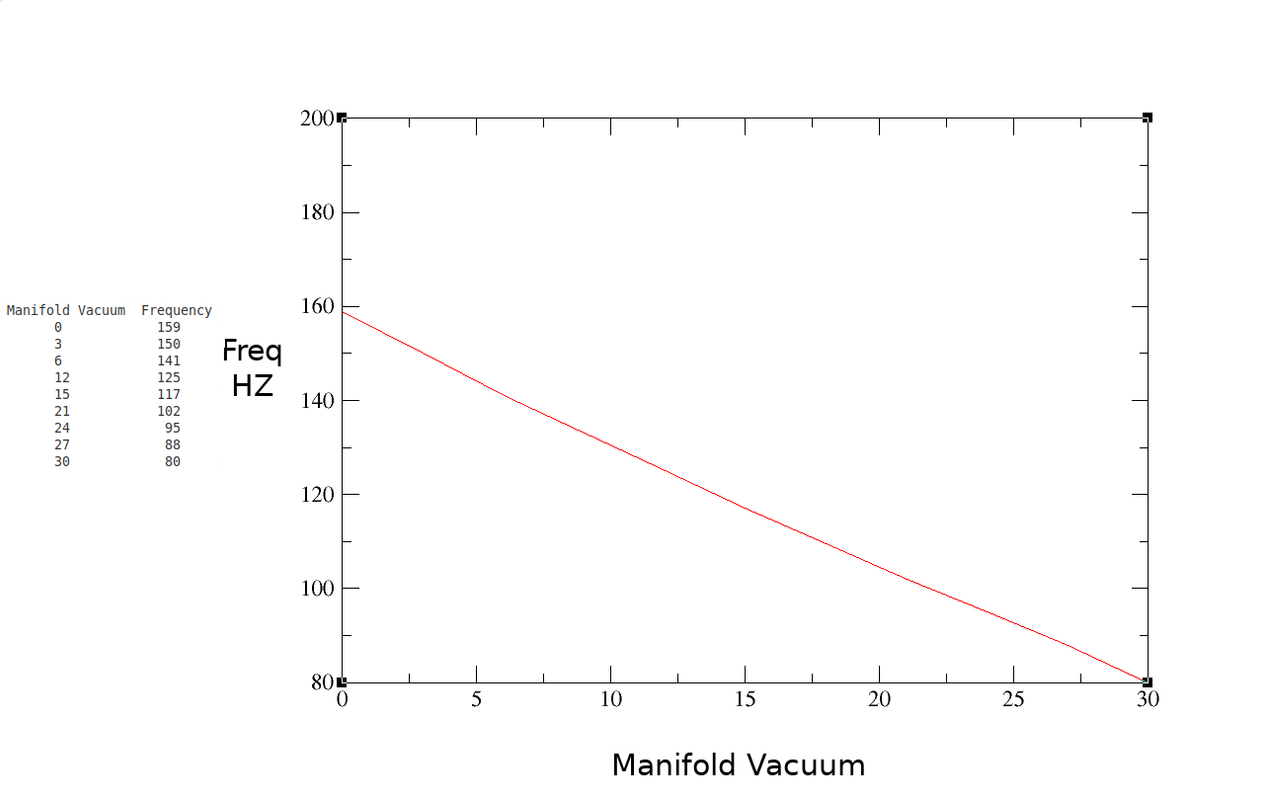

Ford decided to forge an unusual path when it comes to Manifold Atmospheric Pressure (MAP) sensors. Most manufacturers chose a simple 0-5v signal, with decreasing manifold pressure indicating less voltage at the sensor output. Ford used a frequency generator instead.

Ford uses a 5v input, and the sensor is grounded through signal return as other manufacturers. The output however, is a 5v square wave whose frequency varies with manifold pressure.

Typical sensor values will swing between approximately 100 HZ at idle and 151 HZ at wide open throttle. Accurate diagnosis requires a frequency meter. Nowadays they can be bought cheaply, back in the 80's they were prohibitively expensive for the average technician. We resorted to Ford's method for checking sensor output, which is setting a voltmeter to DC volts and looking for around 2.5 volts on the center MAP output pin (5 volts at a 50% duty cycle equals an average of 2.5 volts). This won't tell you the frequency of the signal, but will tell you if the sensor is completely dead.

Many MAP issues were actually vacuum issues. Hydrocarbon vapor can dissolve the potting inside the sensor, which can plug the vacuum hose. Rubber vacuum hoses crack and split, vacuum nipples on intakes plug with carbon.

A spare MAP sensor is something every Ford tech had in his toolbox for diagnosis.

MAP and BARO sensors are identical, BARO sensors will not have a vacuum hose attached to them. Be careful when looking at BARO PID's, as Mass Air vehicles may show the PID, but not have a BARO sensor installed. These vehicles will use WOT airflow data to calculate (infer) BARO PID data.