Very nice

@Otto

Mine will be here on Sept 12th if nothing holds it up.

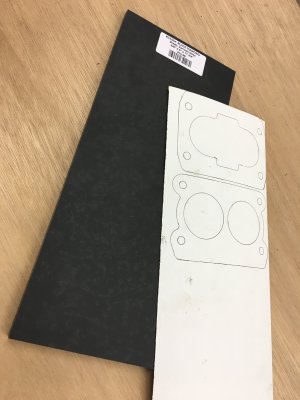

Well, Santa came early this week and the phenolic spacer arrived this morning. It's installed now.

A couple of things:

1) My carb didn't appear to have any vacuum leaks and the gasket looked good but all 4 of the the nuts were finger tight when I took off the carb. Snug but literally finger tight, no wrench required to remove. I did tighten them earlier this year because they were finger tight last time I checked as well and I probably put about 7lbs or maybe a little more of torque into them with a hand wrench. I didn't want to over-torque them but I did want a decent seal. This time, I hit them with blue lock-tite when I snugged them down. Again, I probably put 7 lbs - 10 lbs of torque on them. I reused the gasket on the adapter funnel and put a new one between the cab and the spacer.

2) It's odd that I can't seem to find a genuine Redline/Weber spacer for the 38/38. I have one for a 32/36 in the Redline packaging and a bunch of 32/36 gaskets too but none of the dealers I checked with had a legit 38/38 in stock. They all said out of stock for the 38/38 part.

3) The Ebay one that arrived, is laser cut or cut on a CNC from the looks of it. It's fine but it is not a perfect fit and needed a little finessing to fit properly. That said, it is well worth the $20 + postage that I paid and I highly recommend it.

The install would have literally been a 10 minute install but the holes for the studs on the spacer were off alignment enough to warp it when you forced it into place. Teenager me, would have done something dumb like slap the carb on and force it flat but adult me knows better. I pulled two of the perpendicular positioned studs out so I could release the spacer and then I used a step drill on both sides of the spacer to get enough relief for it to slide into place without any restriction, so it would sit flat. It dragged out maybe 20 minutes or a half hour before I got it done, snugged up and lock-tited.

So far, the verdict is positive. The car started up normally and my warmup lap around the neighbourhood got the engine good and hot but the carb was cool to the touch the way you would hope it was. After it was right up to temp, the carb was still cool so I redid the idle for best lean idle and as it turns out I was able to turn the air screws in another 1/4 turn, leaning it out a little more. I'll keep a close eye on it over the next little while. I really need an AFR gauge to dial it in right.

On a related note, lately I've been doing a mix of city and highway driving and even with the big carb and choppy camshaft, I'm getting around 23 miles per gallon. I'm really happy with the fuel economy.