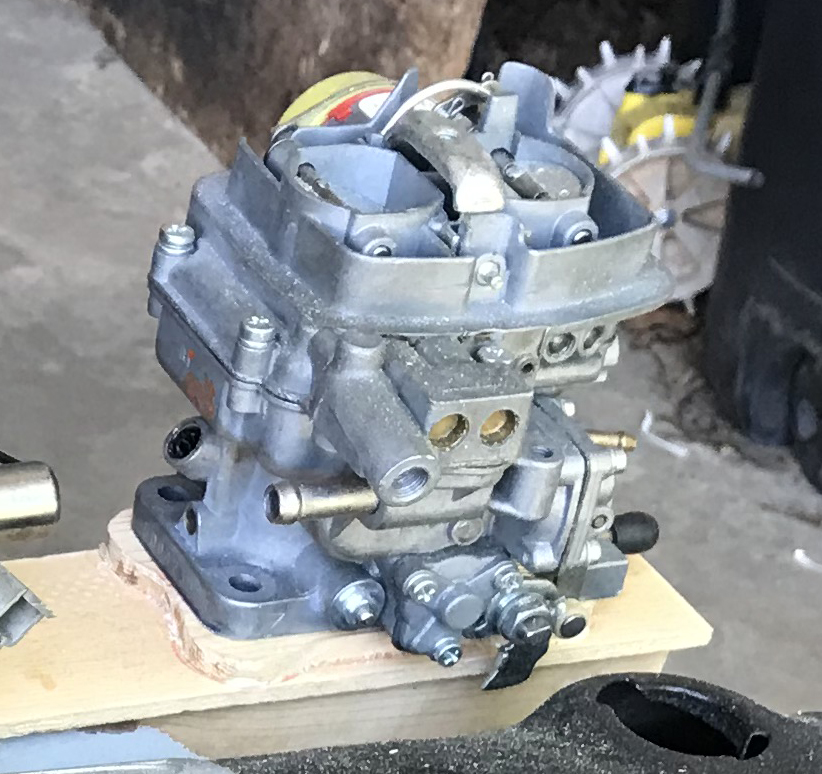

was wondering, is the port in the manifold, just below the carb, the PVC connection? (where I have the cutout on my pattern)

... believe all PCV's used the manifold to carb alum. OEM adapter. Lower manifold port would be used for Auto tranny Modulator vacuum and accessory vacuum taps for vacuum wipers, coolant switched advance emissions 2-way diaphragm dist,' etc... . Holley 2300 2bbl, 4bbl , AFB, etc have 3/8 vac port integral.

Put your finger over ported vacuum - there's almost no vacuum (and no advance) at idle with throttle blade in position for that port. Manifold vacuum to distrib' adds advance at idle.

have fun

. ,,

,,

AUTOMATIC:

... believe all PCV's used the manifold to carb alum. OEM adapter. Lower manifold port would be used for Auto tranny Modulator vacuum and accessory vacuum taps for vacuum wipers, coolant switched advance emissions 2-way diaphragm dist,' etc... . Holley 2300 2bbl, 4bbl , AFB, etc have 3/8 vac port integral.

Put your finger over ported vacuum - there's almost no vacuum (and no advance) at idle with throttle blade in position for that port. Manifold vacuum to distrib' adds advance at idle.

have fun

.

,,

,,

AUTOMATIC:

great Mike your all set for the correct type valve cover and other parts!

great Mike your all set for the correct type valve cover and other parts!  well that's a bummer on those new Pistons Mike. With the stock type 250 cast piston you will be down the hole .030 more then the Ausie piston. On the deck cut I doubt normally that he would of took much more than .010 to .020 off, but even if the pistons do end up out the top of the block .010 with a .044 Victor head gasket the quench would be near perfect at .034. With a Felpro .050 then you could be out the top of the deck .015 or .020 and still be at a .035 or .030 quench. Might work out yet and you could open up the head chamber around the valves for a little better flow too. Is there a chance after he has the crank turned down you could get the block back and do a mock up to see were your at now? Is your head a large chamber one? Good luck

well that's a bummer on those new Pistons Mike. With the stock type 250 cast piston you will be down the hole .030 more then the Ausie piston. On the deck cut I doubt normally that he would of took much more than .010 to .020 off, but even if the pistons do end up out the top of the block .010 with a .044 Victor head gasket the quench would be near perfect at .034. With a Felpro .050 then you could be out the top of the deck .015 or .020 and still be at a .035 or .030 quench. Might work out yet and you could open up the head chamber around the valves for a little better flow too. Is there a chance after he has the crank turned down you could get the block back and do a mock up to see were your at now? Is your head a large chamber one? Good luck