You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

250 build

- Thread starter 69stang_250

- Start date

big difference between a good 'machinist' and a good 'businessman'.

Sometimes ya gotta take yer pick (unfortunatly).

I picked 'machinist' (still had a lill triuble) as I imagine most of us would.

Had the rig since '83 so 'no rush'. Was I happy, no, but I control if I am or not.

On the other hand I'm not some 1 w/$ so just gettin the job done well is a thrill 2 me.

8)

Sometimes ya gotta take yer pick (unfortunatly).

I picked 'machinist' (still had a lill triuble) as I imagine most of us would.

Had the rig since '83 so 'no rush'. Was I happy, no, but I control if I am or not.

On the other hand I'm not some 1 w/$ so just gettin the job done well is a thrill 2 me.

8)

BCOWANWHEELS

Well-known member

go get your stuff, the LORD IS trying to tell you something here. listen up................ theres tons of quality" engine machine shops out there. a ford 6 isn't anything special. don't put up with any attitude, slowness or excuses. ever. move on

So I have done some more reading and ran into some info on Piston speeds and safe operating limits of pistons.

With looking at what the piston speeds on a 250 is,I will be going with forged pistons now. Not really in my budget, but I will adjust where I need to.

Here are a few questions for you guys.

What is the best quench gap when using forged pistons? 0.03? 0.045? ????

Would it hurt having the piston out of the bore .01? I ask because of the .050 head gasket.

I plan on getting Auto Tech to make a 255 style piston with the 1.585 CH with a dish to keep my CR right at 10:1.

I will be throwing in a CS 280 108 LS Cam. with 1.6:1 rockers the lift will be .512 according to the CI web page. How deep would the dish need to be in order to

clear the piston?

My thought is getting that .512 lift, head flow will be about as good as should need to get this engine performing.

These are a few pics of the car after the paint was done. Ready to get this thing back!

Thanks for any input yall.

With looking at what the piston speeds on a 250 is,I will be going with forged pistons now. Not really in my budget, but I will adjust where I need to.

Here are a few questions for you guys.

What is the best quench gap when using forged pistons? 0.03? 0.045? ????

Would it hurt having the piston out of the bore .01? I ask because of the .050 head gasket.

I plan on getting Auto Tech to make a 255 style piston with the 1.585 CH with a dish to keep my CR right at 10:1.

I will be throwing in a CS 280 108 LS Cam. with 1.6:1 rockers the lift will be .512 according to the CI web page. How deep would the dish need to be in order to

clear the piston?

My thought is getting that .512 lift, head flow will be about as good as should need to get this engine performing.

These are a few pics of the car after the paint was done. Ready to get this thing back!

Thanks for any input yall.

Attachments

I measured .117 before removing the pistons on 3 cylinders. I figured if #s 1, 3, and 6 measured the same It should be good.

I was going to have the block decked some, unless you guys think I would be better off just getting pistons with a zero deck height.

Thanks! I have never been a fan of white cars, but this one looks good to me.

Once I get the car done, I may go back and have them blackout the light buckets, tail light panel, trunk lid, and hood.

I was going to have the block decked some, unless you guys think I would be better off just getting pistons with a zero deck height.

Thanks! I have never been a fan of white cars, but this one looks good to me.

Once I get the car done, I may go back and have them blackout the light buckets, tail light panel, trunk lid, and hood.

I order the pistons CH .010" shy of zero deck.

After you get the pistons, temporarily install 1 and 6 without rings and measure the actual amount needed off the block to get zero deck then cut the block deck accordingly.

It is OK to have the pistons .010" above deck providing no part of the head gasket protrudes into the cylinder where it can make contact with the piston.

How did you measure the CH of the stock pistons?

After you get the pistons, temporarily install 1 and 6 without rings and measure the actual amount needed off the block to get zero deck then cut the block deck accordingly.

It is OK to have the pistons .010" above deck providing no part of the head gasket protrudes into the cylinder where it can make contact with the piston.

How did you measure the CH of the stock pistons?

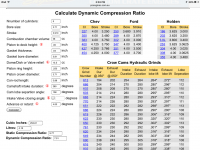

So I grabbed what I gathered your build specifics were (I could have missed some stuff) and this is where you would sit me thinks. I haven't completely rung out the cam event stuff. It's been checked against one example I found online but that might be off a bit.

================================================

INPUT - BUILD PARAMETERS

================================================

Block Specifications:

Cylinder Bore = 3.68 in

Centerline to Deck Height = 9.469 in

Rod Length = 5.88 in

Stroke = 3.91 in

Piston Dish Volume = 6.5 cc

Piston Compression Height = 1.585 in

Cylinder Head Specifications:

Combustion Chamber Volume = 50 cc

Intake Valve Diameter = 1.75 in

Exhaust Valve Diameter = 1.5 in

Rocker Arm Ratio = 1.6:1

Cylinder Head Gasket Dimensions:

Gasket Diameter = 3.75 in

Gasket Crush Height = 0.05 in

Camshaft Specifications and Events:

Intake Duration = 280 deg

Exhaust Duration = 280 deg

Lobe Separation Angle = 108 deg

Cam Intake Lift = 0.32 in

Cam Exhaust Lift = 0.32 in

Ground-in Advance = 0 deg

Camshaft Installation Advance = 4 deg

Intake Opening Angle = 36 deg BTDC

Intake Closing Angle = 64 deg ABDC

Exhaust Opening Angle = 76 deg BBDC

Exhaust Closing Angle = 28 deg ATDC

Valve Overlap = 64 deg

================================================

OUTPUT

================================================

Engine Displacement = 250 in^3

Rod to Stroke Ratio = 1.5:1

Rod Angle = 19.42 deg

Resulting Deck Height = 0.049 in

Squish Distance = 0.099 in

Static Compression Ratio = 10.1:1

Dynamic Compression Ratio = 8.24:1

Intake Valve Lift = 0.512 in

Exhaust Valve Lift = 0.512 in

================================================

INPUT - BUILD PARAMETERS

================================================

Block Specifications:

Cylinder Bore = 3.68 in

Centerline to Deck Height = 9.469 in

Rod Length = 5.88 in

Stroke = 3.91 in

Piston Dish Volume = 6.5 cc

Piston Compression Height = 1.585 in

Cylinder Head Specifications:

Combustion Chamber Volume = 50 cc

Intake Valve Diameter = 1.75 in

Exhaust Valve Diameter = 1.5 in

Rocker Arm Ratio = 1.6:1

Cylinder Head Gasket Dimensions:

Gasket Diameter = 3.75 in

Gasket Crush Height = 0.05 in

Camshaft Specifications and Events:

Intake Duration = 280 deg

Exhaust Duration = 280 deg

Lobe Separation Angle = 108 deg

Cam Intake Lift = 0.32 in

Cam Exhaust Lift = 0.32 in

Ground-in Advance = 0 deg

Camshaft Installation Advance = 4 deg

Intake Opening Angle = 36 deg BTDC

Intake Closing Angle = 64 deg ABDC

Exhaust Opening Angle = 76 deg BBDC

Exhaust Closing Angle = 28 deg ATDC

Valve Overlap = 64 deg

================================================

OUTPUT

================================================

Engine Displacement = 250 in^3

Rod to Stroke Ratio = 1.5:1

Rod Angle = 19.42 deg

Resulting Deck Height = 0.049 in

Squish Distance = 0.099 in

Static Compression Ratio = 10.1:1

Dynamic Compression Ratio = 8.24:1

Intake Valve Lift = 0.512 in

Exhaust Valve Lift = 0.512 in

I used a dial indicator I borrowed and I also measured with some calipers I have.

I measured on 4 corners of the pistons where the pins are and 90* off of those.

Ok. that is what I was wondering. I have not found what the felpro head gasket bores are, but I have read on a few forums that it is 3.81.

Do any of you know if this is correct?

I measured on 4 corners of the pistons where the pins are and 90* off of those.

Ok. that is what I was wondering. I have not found what the felpro head gasket bores are, but I have read on a few forums that it is 3.81.

Do any of you know if this is correct?

All of the FelPro PermaTorque head gaskets I have ever used never protruded into the cyclinder bores even at .060 over.

X2 the paint and body work look outstanding!

X2 nothing wrong with having a piston .010 to .015 out the top, a minimum quench is better in the range of .035 to .050 their are some even runing as little as .030 with the steel rods in race apts. then adjust your pistion dish CC's to get your compression ratio where you want it. Have you considered also using a longer Rod (300 or 2.3) as "62Ranchero" did in his very semular 250 build? Good luck

X2 the paint and body work look outstanding!

X2 nothing wrong with having a piston .010 to .015 out the top, a minimum quench is better in the range of .035 to .050 their are some even runing as little as .030 with the steel rods in race apts. then adjust your pistion dish CC's to get your compression ratio where you want it. Have you considered also using a longer Rod (300 or 2.3) as "62Ranchero" did in his very semular 250 build? Good luck

Gene Fiore

Famous Member

Yes, 3.81 is correct.69stang_250":1vqjest7 said:I have not found what the felpro head gasket bores are, but I have read on a few forums that it is 3.81.

Do any of you know if this is correct?

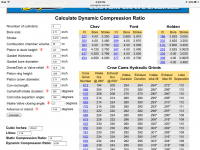

Bobcat-

here is what my build will be.

Bore = 3.71

rods = 5.88

stroke = 3.91

piston dish = 13.5? ( this will be adjusted base off the head cc)

Piston CH = 1.585( this may change )

CC Volume = 58? ( this is the number I hope it ends up at but will be adjusted if lower)

intake = 1.84

exhaust= 1.50

Rockers = 1.6:1

head gasket = .050 crush ( i do not know for sure what the bore is for the gasket)

Cam

CS 280

LS = 108

Adv = 0

installed Adv = 4 ( may just install straight up )

out put

Dis= 253

Deck height = -.010 ( this is what I am shooting for )

quench area = .040

Compression = 10:1

DCR= 8.09 ( this is going with a 3.81 gasket bore )

valve lift = .512

here is what my build will be.

Bore = 3.71

rods = 5.88

stroke = 3.91

piston dish = 13.5? ( this will be adjusted base off the head cc)

Piston CH = 1.585( this may change )

CC Volume = 58? ( this is the number I hope it ends up at but will be adjusted if lower)

intake = 1.84

exhaust= 1.50

Rockers = 1.6:1

head gasket = .050 crush ( i do not know for sure what the bore is for the gasket)

Cam

CS 280

LS = 108

Adv = 0

installed Adv = 4 ( may just install straight up )

out put

Dis= 253

Deck height = -.010 ( this is what I am shooting for )

quench area = .040

Compression = 10:1

DCR= 8.09 ( this is going with a 3.81 gasket bore )

valve lift = .512

I am looking at the 300 rods right now.

I guess I would just need to find a set at a good price if I go that rout.

The problem with that is just the price factor.

I guess I would just need to find a set at a good price if I go that rout.

The problem with that is just the price factor.

You might try PM ing The French Town Flyer he posts on the Big Six 240 / 300 forum he may have a set. The ones you want to find are the early 300 rods without the oil spit holes they should be the 1965 to 1967 year versions. Set of cores should be somewhere around $60.00 to $100.00 range you likely could recoup most or all of that back by selling off your 250 rods. Good luck  edited

edited

edited

editedWell, I think I'm gonna stay with the stock rods. I know using the 300s will help with side loading, but I don't think I'm gonna go with them. I'm starting to think I need to stop reading and get to the build lol!

The more I read, the more I question myself and start to over think stuff.

But I am glad I read what I did.

One thing I have noticed with those that have ran their engine on a synonym, is that most of these engines make their peak power in the 4500-5000 RPM range. Does anyone's engine make power up to 5500-6000 range?

That is where the stock Pistons are iffy.

The more I read, the more I question myself and start to over think stuff.

But I am glad I read what I did.

One thing I have noticed with those that have ran their engine on a synonym, is that most of these engines make their peak power in the 4500-5000 RPM range. Does anyone's engine make power up to 5500-6000 range?

That is where the stock Pistons are iffy.

69stang_250":29lc9ye1 said:Well, I think I'm gonna stay with the stock rods. I know using the 300s will help with side loading, but I don't think I'm gonna go with them. I'm starting to think I need to stop reading and get to the build lol!

The more I read, the more I question myself and start to over think stuff.

But I am glad I read what I did.

One thing I have noticed with those that have ran their engine on a synonym, is that most of these engines make their peak power in the 4500-5000 RPM range. Does anyone's engine make power up to 5500-6000 range?

That is where the stock Pistons are iffy.

The stock 250 rods just need to have the forging lines ground off the beams then shot peened.

Then resize the rods with ARP bolts and you will be fine.

If the head flows 200 cfm or more then peak HP can easily be above 5000 rpm with cam durations in the 230 degree range.

The 58cc chamber coupled with the 13.5cc dish is going to knock your SCR down to 8.7 and DCR to 7.1 (assuming 4* advance on the cam). This number drops to 6.9 when installed straight up.

With the stock rods and a piston CH of 1.585, you'll still be left with a 0.049 piston shortfall.

Again, keeping that chamber and dish, using a fictional 1.634 piston CH, essentially zeroing the deck, you're left with 9.56:1 SCR and 7.75 DCR.

Are you sure on that 58 cc? I was assuming the aluminum head before with a 50 cc chamber. That number I got off of the CI website, but I know there's some variability in there depending on which casting you ended up with.

Going with 0.030 over, 13.5 cc dish, 50 cc chamber, on a stock rod and piston CH of 1.585, you'd be looking at SCR = 9.49 DCR = 7.69 with a 0.049" piston shortfall. You could mill the deck a bit to get to 10:1 as a compromise. Shaving 0.30" off the deck puts you right at 10:1 SCR and 8.16:1 DCR (4* advanced).

With the stock rods and a piston CH of 1.585, you'll still be left with a 0.049 piston shortfall.

Again, keeping that chamber and dish, using a fictional 1.634 piston CH, essentially zeroing the deck, you're left with 9.56:1 SCR and 7.75 DCR.

Are you sure on that 58 cc? I was assuming the aluminum head before with a 50 cc chamber. That number I got off of the CI website, but I know there's some variability in there depending on which casting you ended up with.

Going with 0.030 over, 13.5 cc dish, 50 cc chamber, on a stock rod and piston CH of 1.585, you'd be looking at SCR = 9.49 DCR = 7.69 with a 0.049" piston shortfall. You could mill the deck a bit to get to 10:1 as a compromise. Shaving 0.30" off the deck puts you right at 10:1 SCR and 8.16:1 DCR (4* advanced).

Puller - I am going to clean and polish the rods in the next day or so. I have done polishing on metals before so I'm sure I can tackle that and then get the machine shop to shot peen them for me. Yeah, that is why my views on the forged Pistons have changed. Once you get above 5300 rpm those piston speeds are at or above 3500 fpm and I've read that is about the limit on stockers.

Bobcat - I think you have your math wrong man. Here is what I am using and how I got my compression numbers. I may go with a 56cc Combuation chamber to get the 10:1 or I'll adjust the piston dish volume.

Bobcat - I think you have your math wrong man. Here is what I am using and how I got my compression numbers. I may go with a 56cc Combuation chamber to get the 10:1 or I'll adjust the piston dish volume.

Attachments

The numbers you plugged in are different than what I used. The zero deck height would have to assume a custom piston that is significantly taller than the stock 255 piston. You also have 0.04" in for the gasket crush height. At a 3.81 diameter, that makes a difference too. I don't try to compute the volume above the ring landing though but I'm not sure that wil be a large contributor. I'll double check my numbers tonight though.

Similar threads

All Small Six

250 Engine Build

- Replies

- 23

- Views

- 1K

All Small Six

Help! Did I just screw up my new build?

- Replies

- 150

- Views

- 4K

All Small Six

Back in the Saddle

- Replies

- 85

- Views

- 2K

- Replies

- 8

- Views

- 976

All Small Six

Winter Project: Better breathing with a large log

- Replies

- 138

- Views

- 7K