I should also add my fan is on for the vast majority of the time because I have it set to kick on at 160 because at 170 or 180 it gets way too close to overheating for my liking since it takes a bit to actually cool

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Weber 32/36 rough idle

- Thread starter beanmiester

- Start date

This relates to all small sixes

When I was trying to get mine to work, I put my fan relay on a switch. Even running full time, I couldn’t keep the carb from Vapour locking. That was without a phenolic spacer and without a heat shield between the carb and engine and with my gas line basically on the valve cover. My engine compartment is ridiculously hot but blowing hot air around the engine compartment was just enough to keep it from Vapour locking.I should also add my fan is on for the vast majority of the time because I have it set to kick on at 160 because at 170 or 180 it gets way too close to overheating for my liking since it takes a bit to actually cool

It’s better now that I’ve rerouted my fuel line but I need to install the spacer and head shields before I attempt the electric fan again.

That and why you have oil in the filter housing. I laid out the PCV system in post 169. Is yours correct? If there's oil in the filter housing it is not correct. Either the PCV valve is not functioning correctly, not routed properly, or the engine is very worn out. Oil in the air filter means a large % of the blow by is going up that hose into the filter, which should only be occurring on heavy throttle.So for for now I'm trying to figure out the vacuum situation that way my booster isnt gets crank case fumes

Getting this straight is more important than the shared vacuum port at this point.

A picture of your system would be helpful.

Also, nearly all carbs have a intake vacuum port on them, this could supply the trans.

On my intake with no vacuum port, I used a spacer with a port in it for PCV.

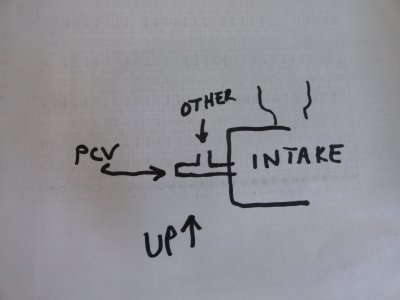

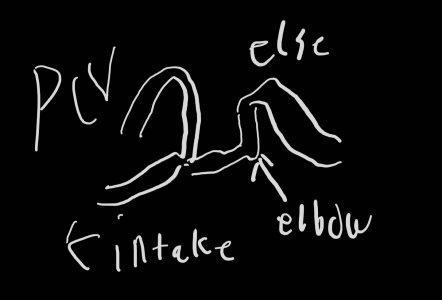

Dang it, I'm confusing threads again- my bad. Thanks for the pic. That Tee where the PCV comes in is in the worst possible place, oil can run directly into the booster. The Tee should be at /in the intake, with the PCV going straight into the intake, and the other vacuum sources coming in from above. A Tee that threads directly into the intake provides the best flow.View attachment 26591

The line that ties into the blue metal line is how the vacuum is routed. Under the metal support is a tee that connects to the transmission.

I dont have a line that goes into the air cleaner and I don't see anywhere to hook one up to.

It's obvious you have an attractive planned-out engine bay. Looks nice. Rerouting the lines may not look as nice. I have spent hours on end routing electric lines and hoses for a clean look, so I get it.

Attachments

Last edited:

That's better. No matter what, every time the vacuum spikes from low to high- like every gear shift, or decelerating- oily vapor is shot toward every far-end of the system.

It's a fluid dynamic characteristic- when vacuum increases in an airmass with heavy particulates, the particulates are drawn in the opposite direction of the vacuum source, and toward the walls of the constraining tube.

A good visual of this principle is the windshield repair kits. Some glue is put on a crack, and a suction cup applies vacuum. Logic would say the vacuum would draw the glue toward the vacuum cup. In reality, the vacuum causes the glue to move to the farthest, deepest recesses of the crack.

It will take a while for blow by residue to affect the modulator valve and brake booster, but don't doubt it's getting in there, because it is. The closer to the intake the blow by can enter it, the less of that oil air is available in the hose to activate the booster/modulator.

Probably overkill, I always isolate PCV from everything else. Even when, in one case, I had to buy a carb spacer and drill/fab a port in it for PCV and use the intake port for the rest.

It's a fluid dynamic characteristic- when vacuum increases in an airmass with heavy particulates, the particulates are drawn in the opposite direction of the vacuum source, and toward the walls of the constraining tube.

A good visual of this principle is the windshield repair kits. Some glue is put on a crack, and a suction cup applies vacuum. Logic would say the vacuum would draw the glue toward the vacuum cup. In reality, the vacuum causes the glue to move to the farthest, deepest recesses of the crack.

It will take a while for blow by residue to affect the modulator valve and brake booster, but don't doubt it's getting in there, because it is. The closer to the intake the blow by can enter it, the less of that oil air is available in the hose to activate the booster/modulator.

Probably overkill, I always isolate PCV from everything else. Even when, in one case, I had to buy a carb spacer and drill/fab a port in it for PCV and use the intake port for the rest.

Those of you running electric fuel pumps if you have pictures of how you mounted it could you send them please?

I dont see anywhere that really looks like a good spot. Its all kinda meh under there for placement

I dont see anywhere that really looks like a good spot. Its all kinda meh under there for placement

Hi,ive built a mild performance 200 engine for a client and its got the AUSSIE performance 2v head on it from the 250 engine,extractors,mild street cam,flat top 30 thou pistons,5 spd manual,would the 38/38 carb(are they more thirsty ?) be a better option than the recommended 32/36.Its built as an every day driver,not a racer,ive been told run a fuel line regulator and set it 3psi ?Any advice gladly accepted.Thanks MikeYes, that is supposed to be ported vacuum. It should be completely closed with no vacuum at idle.

How many turns in is the idle speed screw? You can back it up a quarter or half turn at a time, keeping track of how many turns it takes for it to just kiss the throttle stop lever without it opening the throttle blades. It should be no more than 1-1/2 turns.

If it’s less than 1-1/2 turns and it’s pulling vacuum, there’s a problem with the carb. If it’s more than 1-1/2 turns, you’ll need to do the best lean idle procedure I linked earlier.

Hi Mikez, welcome.Hi,ive built a mild performance 200 engine for a client and its got the AUSSIE performance 2v head on it from the 250 engine,extractors,mild street cam,flat top 30 thou pistons,5 spd manual,would the 38/38 carb(are they more thirsty ?) be a better option than the recommended 32/36.Its built as an every day driver,not a racer,ive been told run a fuel line regulator and set it 3psi ?Any advice gladly accepted.Thanks Mike

Yes 3 psi is the standard for the Weber.

The two carbs in question have very different character, since the 32/36 is progressive and the 38/38 is synchronous. So the 38/38 has 223% more airflow than the 36/38 for any given throttle position (up to where the secondary cuts in on the 36/38.) This will affect off-idle response and driver feel in the motion of the accelerator pedal.

The specific cam overlap@ .050", the LSA and manual/auto trans, combined with driving environment/driver style- key players in the carb choice.

The good breathing head is a plus over the log head/carb adapter if the larger 38/38 is chosen.

Hey Mikez! Welcome too.

Definitely do a regulator. If you the Webber in a kit it comes with one. Look at Clifford performance. Tell them about your engine build and the will pre-tune it as well. It would be a good idea to add a pressure guage as well. You will get recommendations for both carbs. I would say for street drivability go with the32/36. There are threads here discussing both. By the way too, it is good to start your own thread on your own topic. They sometimes wander but we try to keep them on topic with the title

I thought I lost this post, but it showed up. ???

And what Frank said

Definitely do a regulator. If you the Webber in a kit it comes with one. Look at Clifford performance. Tell them about your engine build and the will pre-tune it as well. It would be a good idea to add a pressure guage as well. You will get recommendations for both carbs. I would say for street drivability go with the32/36. There are threads here discussing both. By the way too, it is good to start your own thread on your own topic. They sometimes wander but we try to keep them on topic with the title

I thought I lost this post, but it showed up. ???

And what Frank said

Idk if my input is worth much from how messed up my carb was lol but I like the 32/36. Even though the carb was dumping fuel it still had a great idle when the engine wasn't getting overwhelmed by the fuel. A few times I got it so smooth you could hardly feel the engine running and it was soooo quiet. Sadly those moments were short lived to 5 minutes or so.

Hi Mike,Hi,ive built a mild performance 200 engine for a client and its got the AUSSIE performance 2v head on it from the 250 engine,extractors,mild street cam,flat top 30 thou pistons,5 spd manual,would the 38/38 carb(are they more thirsty ?) be a better option than the recommended 32/36.Its built as an every day driver,not a racer,ive been told run a fuel line regulator and set it 3psi ?Any advice gladly accepted.Thanks Mike

Man, I wish I had that Aussie head on mine. That would give me a lot better flow. I have the original small log head with Silv-o-lite shallow dish pistons. I measured everything to a little more than 8.5:1 compression and I’ve got the T5 conversion. I am using the 38/38 and it does run a little rich. I need to add an AFR gauge so I can really dial it in.

I think the 38/38 is a great setup. Even with the poor flow of the small log head, I average 23 MPG in a mix of city highway and it’s pretty zippy. It would only improve with the Aussie head and a decent intake. The next step is fuel injection.

Alright party people. I've tried the weber a second time and im running into issues with the adapter. I cant get the carb to adapter gasket to seal. So i either need a different adapter or im going to try a plastic spacer that redline sells. Maybe that will distribute the pressure better.

Attachments

But when I completely closed off the choke to reduce the air that comes in the engine sounds very healthy. So i think this carb will be promising if I can stop this vacuum leak

Also with that adapter the studs on the manifold are slightly too tall to where you have to hold the adapter up to thread on the nuts otherwise there isnt enough room and the nuts gouge the adapter trying to tighten them

Also with that adapter the studs on the manifold are slightly too tall to where you have to hold the adapter up to thread on the nuts otherwise there isnt enough room and the nuts gouge the adapter trying to tighten them

Similar threads

- Replies

- 29

- Views

- 4K

- Replies

- 7

- Views

- 3K

- Replies

- 5

- Views

- 3K

- Replies

- 19

- Views

- 5K

- Replies

- 38

- Views

- 8K