TrickSix

Famous Member

How about these?

https://ebay.us/m/5eU0pW

https://ebay.us/m/5eU0pW

How about these?

https://ebay.us/m/5eU0pW

As of a 16 months ago Sealed Power parts of this nature were still USA made. I can not confirm it since then.I like that those would be larger than the stock exhaust valves and at 1.46875” is smaller than 1.5” and might be able to cut the original seat for it.

The stems are oversized. I’m not sure if that is an advantage but it doesn’t bother me. The only concern I would have is that they are Sealed Power and not OEM so they may not be made of suitable material for an exhaust valve. Does anyone know if that’s the case?

Good find. Thanks for posting those.

As of a 16 months ago Sealed Power parts of this nature were still USA made. I can not confirm it since then.

Not sure if this is relevant.Intake is : MEL V5328 from rockauto.

They are for a 1990 Toyota Pu 2.4l gasoline l4. The exhaust valves are for the same engine.

Perfect fit for my big log head. Valve guides cut for 8mm stems and seals, springseats cut for ls size springs. With The ls valve locks, one will need a 2mm lashcap. Other valve locks might work beter in locating the stem abow the retainers.

Good luck!

I have learned -been told- that when you get into the upper limits of compression, it’s more about dynamic compression and that is related to how aggressive your cam is and its set up for timing. An aggressive cam will lower your dynamic compression. How much can be figured but not much info on how the small 6 reacts.

I think that's what I was looking for.I would run the numbers with your cam on a dynamic compression tool and see where you are at. 94 octane will give you a buffer

I don't know the duration of the stock cam on the small6. If it were a big6, both cams above INCREASE dynamic compression. Almost all the aftermarket cams do, they have less gross duration than the stock cam. They also increase dynamic by increased effective .050" duration cylinder filling.

When crunching camshaft stats, keep in mind that all measurements are in crankshaft degrees, except the LSA (Lobe Center) which is in camshaft degrees. Thus Don's cam @ 108* LSA has FOUR degrees less gross duration for the same duration # than a cam @ 110* LSA. Don's cam, even at 274* would still increase compression over a stock cam (remember, example is on a 300)

Stock (big6) cam: 268* intake duration @ 110* LSA. , retarded 4* This cam closes the intake valve 68* after bottom dead center.

Your Clay Smith cam: 264* intake duration @ 110* LSA, advanced 4*. this cam closes the intake valve 58* after BDC. That's 10* more piston upstroke with the valve closed on compression stroke- more dynamic compression.

On a big6 with EFI head, using awasson's cam above, the stock cam has 6.8:1 dynamic compression, the Clay Smith has 7.3:1. The Clay Smith would require 93 octane gas in a 300, the stock cam 87 octane.

To calculate intake valve closing point: (gross duration divided by 2) + LSA - 180.

If all the boxes are filled in correctly, this is the compression calculator to use. Don't guess, small changes in deck clearance, gasket thickness and head volume make a notable difference in CR. If I'm searching for maximum compression for a given fuel grade, I find the target intake valve closing point, then calculate "backwards" to the cam duration that meets that parameter. This is why the Crower cam on my 240 build is retarded 1* rather than advanced. Flat top pistons, and 26 thou shaved off the block. I am able to use regular gas- barely. If the cam was advanced, no way. It has 9.65:1 static compression and 7.4:1 dynamic. According to this forum, the small6 can withstand higher compression numbers on a given fuel grade.

https://uempistons.com/p-27-compression-ratio-calculator

Keep us posted

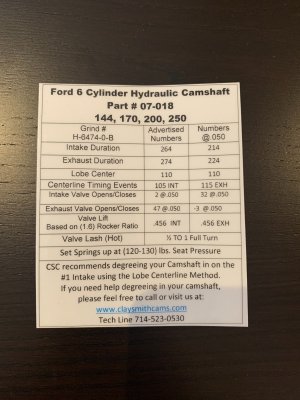

This is my card:

I’m at around 10:1 static and hoping to use 91 octane. I have been told I’ll be ok and that it will be interesting to see.

Sooo, I’ll see

But, famous last words: you’ll be ok!!