mike1157":39hkvuvv said:

When I built my engine, and had originally planned to use a log head, the whole issue of how to deal with the 1000 degree " furnace" that would be directly beneath the intake gave me all the reasons in the world not to. When the opportunity came up here to buy the Crossflow head I jumped on it.

Despite all of the additional modifications required to make that head fit a us block, and all of the logistical issues getting parts from Australia to make it work, the fact that I can put my hand on the intake manifold and leave it there when the water temp gauge reads 200 becomes the number one reason to do it.

The looks you'll get at the cruise-ins is directly related to that. Nobody here in the us has a Crossflow headed banger.

Which brings me to this story:

Last year, I was at Cruisin the Coast. A big giant car show for domestics from 1987 down. The last day, I backed in under a huge Spanish oak right next to a 1961 Corvette on one side, and a 80's chromed out short bed Chevy p/u on the other. The Vette owner, typical for Vette owners, sat in his chair at the back of his car with his wife, seeming mildly perturbed that my androgynous ford was parked next to his pristine classic. I complimented his car as I was getting my chair out of my trunk, and ol Vette dude just grunted something back at me. I set up at the front of the car. All day long, spectators streamed by, glancing at his car, but stopping to talk with me about mine. After a few hours, Vette dude sends his wife to look at what was under my hood that was causing all of the commotion ( he himself was too proud to spend anytime looking at a " Non C2" Corvette). She goes back, and had to tell him " I don't know what that thing is", because after a while,he drags himself outta his chair, and says " I have to see what the hub-bub is with your car,....what am I looking at here" ( probably the 100th time I had to answer that question that day). I don't remember exactly, but I think he actually returned the compliment.

I considered that the high point of the day,...that my pieced together, science experiment managed to get him out of his chair and... Made him look.

Now..back to your dilemma. If that mess of tubes isn't coated that should be priority 1. The may be a radiant barrier that you can have your intake coated in to insulate it better as well, but I still think you're gonna have heat issues.

You do great work, and looking at your engine pics I kept saying to myself, " that's how I'd have done it." Having welded that intake together, you know full well how quickly aluminum takes, and spreads heat when it's applied.

Had I kept the log head, I fully planned to put the plenum on the opposite side of the engine like the factory does sometimes to minimize the heat soak. ( although that'll do little to minimize the exposure of the injectors as they are still immediately north of the exhaust. I also wouldn't have buried the turbo under the tubes, and put that glowing red hot orb in a place to just add even more radiant heat that needed to rise up and just roast everything above it.

But that's just me.

The problem with having to build heat shields is that it ruins all of the beautiful design aesthetic you've got going on.

About the only thing you can do is to maybe build a partition plate that will sequester the header. Maybe add some additional heat insulation blanket to one side of that plate. maybe dedicate a fan that blows directly at the header to try and blow some of that hot air out from under the car.

Or...maybe you put a Crossflow head on it......I know a guy that has one.

Nice one Mike. Best wishes with the Jay Zee.

If ever there was an icon coated in red, gold and black that created as much spark...it's your Gila Monster.

Your advice is welcome.

Right, another seven steps:-

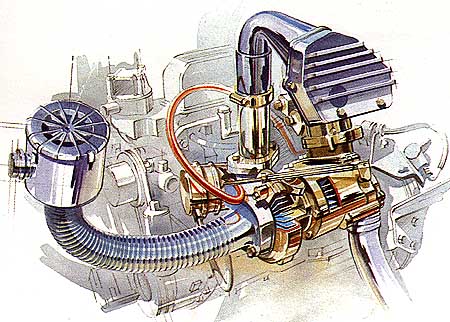

1. Ford used Tickford for there development work on in line sixes well before they picked up Aston Martin and Jaguar. The acquisition of Volvo and access to plug and injector data on the modular in line five and six also brought information back to Dearborn. The squirrel blower was the out come of fixing a whole bunch of TFi and Injector heat issues that really caused some problems at FoMoCo.

2. The Aussie Ford and Holden guys worked through this from 1983-1992 the same way BMW did with the Siamese bored M30 2.0/2.3/M21 Diesel 2.4/Eta 2.7 engines.

3. In BMW'S, the heat sink was controlled by slanting the engine for BMW, but Ford OZ and GM Holden just decided to keep the air entry point cold. The

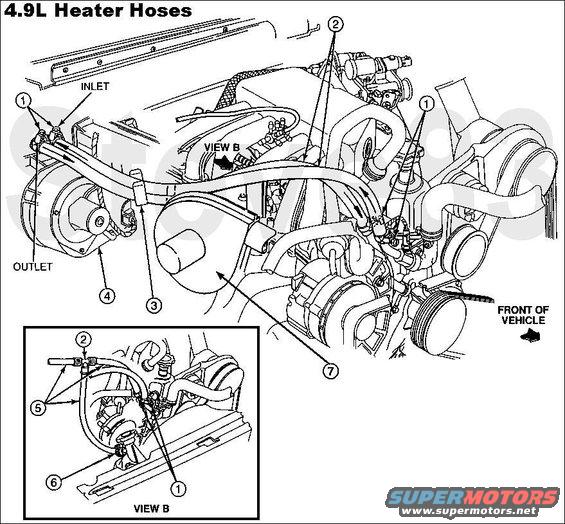

4. The famed squirrel blower duct, um, " Anti Vapor Lock Cooling Fan" was a F150/250/350 E van solution for injector heat.

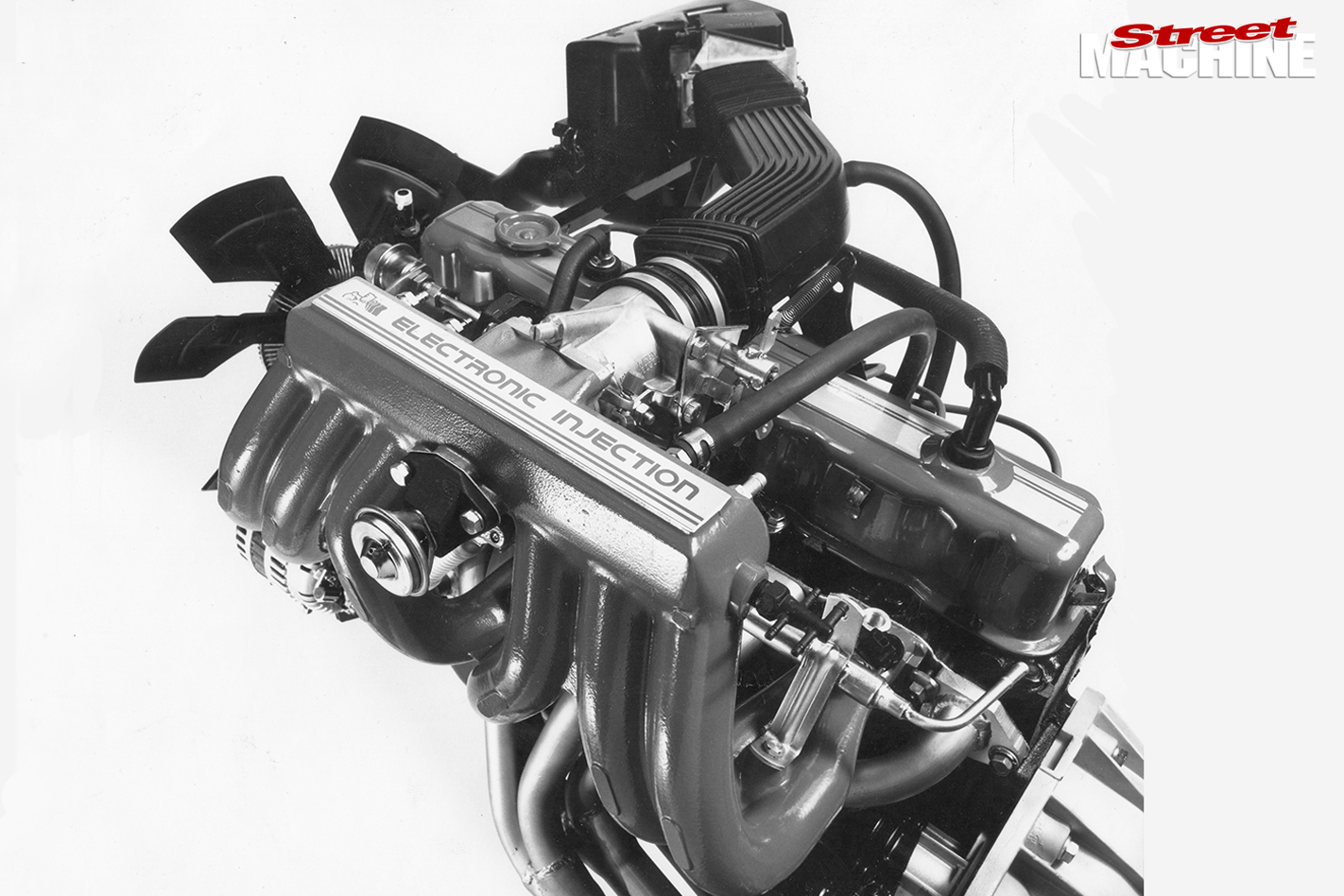

5. When Tickford did the 1992 Falcon XR6, Adding headers in a non cross flow or even the EFI X-flow Ford sixes always hurt performance due to heat saturation close to the injectors.

6. For Ford USA, the 12 or 14 pound per hour injectors run hot, and the blower was Ford USA's response before changing the injectors. (4.9 F-truck/E-Van, or to a lesser extent, but still enough to be a problem, the Aussie 4.1 EFI cross flow or SOHC 3.9/4.0 EFI engines, same deal, but they decided to elimante headers and only use an iron header).

7. Same with the 3.3 liter Electronic Injection 3.3 Holden Commodore 142 hp six from 1985

It has a stainless steel header. The made a really good cold air scoop for it, and figured out how to use the intake runner to be separate, and shielded from the exhaust.

When turboed, generally, people move to ductile iron or higher iron content tube bends.

An " Anti Vapor Lock Cooling Fan" or an ellipsoidal fuel rail cooler will be elegant and will work if you figure out a way to mount it.

Back in my Mini 1275 engine days, the Lotus Engineering conversion to the Turbo 1275 MG Metro used engine heat as a means of making the huge 1-3/4" SU carb heat up. They couldn't care less how much heat hit the carb....one 225 cfm carb would always juice the so called 95 hp 78 cube engine to make well over its advertised hp.

EFi brings with it a duty cycle and fuel handling temperature restriction, and straight off, I'd copy what other car companies do. It is a fine, easy way of making a non cross flow engine change from a stupid 57 hp plodder to a twice as powerful stalwart without problems.

http://www.hybrid-mini.co.uk/metro/Grap ... iagram.jpg

Ford never made a double the Horsepower 1987-1996 300 hp low pressure turbo 4.9 six. If they did, it wouldn't have been any different to the stock 4.9.

The Cross Flow 4.1 AIT Turbo... It had the injectors on the other side, but it had a whole gambit of other problems which required a Anti Detonation Injection system to cover off as canted valve engines run much closer to detonation than wedge head non cross flows.

When Ford Australia and Honda did the first cross flow alloy head, it was always prone to pre-ignition or pinking. Its a Boss 302/351/ X-flow issue that only ever gets fixed when you use a knock sensor. So going another road might seam fair enough, but it also has Sounds like Detonation issues.

Injectors are easy to cool.

A detonation prone X flow requires a specific RX to nail it. The best 1972 351C HO 4V makes 350 hp net verses the best 1969 Shelby's 351w 4V 290 hp net's. 60 extra horses. But the detonation prone engine could break and not finish races despite the extra horsepower.

So you've got to go back to Fixing the Problem.

The Aussie Dick Johnson found an easy another 47 hp net extra with the Cross flow head in the planned 2305 500 CFM carbed 1987 SVO Falcon, 196 hp verses about 149 hp net with the 1972 250 2V. Both ran 9.3:1 compression, but the extra cfm and power came with a lowered detonation threashold. A lot of the turbo guys spend a sh!+ load of money fixing that problem....

Advanced Induction Technologies' David Inall,

MVT's Mike Vine,

DJR's Dick Johnson

....all failed to make it commercially viable, and the used Japans HKS and NormalAIR Garrets best technicians and engineers to fix it.

Look at this beauty....

But look at the extra doo-dads.

My un-tendered advice?

Use the Sixth Finger, the bl

QQdy Squirrel Blower.

A Rule 12v boat cabin blower would do the same job.

Try one of those whistles out and be done with all this henium coated trying.

IMHO, The thermodynamics are all wrong. Yes, NHRA style Crome coating or even the the old Jay Leno Porcelain coated Maserati GT 3500 iron headers...or NASA coating...that works. But Coatings, they do work, but simple

wind rush works better.

Also figured out the oil leak - the oil pan mating surface to the block is a little warped and needs to be flattened - so another problem solved. So I'm really enjoying driving the car - it's running reliably and performing as I'd hoped. I'm still running it a little bit rich so I need to fine tune and make a few adjustments to get it to it's peak performance.

Also figured out the oil leak - the oil pan mating surface to the block is a little warped and needs to be flattened - so another problem solved. So I'm really enjoying driving the car - it's running reliably and performing as I'd hoped. I'm still running it a little bit rich so I need to fine tune and make a few adjustments to get it to it's peak performance. But things are back on track and now I can finish the 10,000 little details on the rest of the car!

But things are back on track and now I can finish the 10,000 little details on the rest of the car!